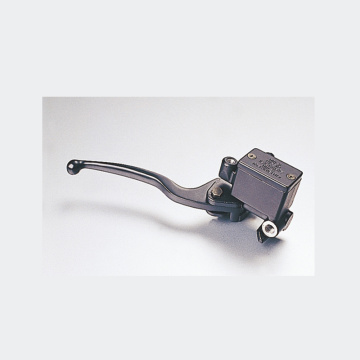

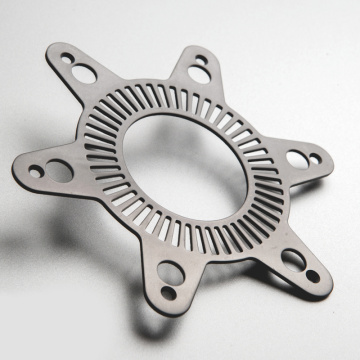

Motorcycle brake electromagnet accessories

-

$14.67≥1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Transportation:

- Air, Express

- Port:

- chongqing

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 20000 Piece/Pieces per Month |

| Supply Ability: | 20000 Piece/Pieces per Month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB |

| Transportation: | Air,Express |

| Port: | chongqing,, |

Product Description

Product Description

1. Name of Motorcycle Vehicle Accessories: NX-6020L electric motorcycle brake suction electromagnet

2. Voltage: 12V 24VDC,

3. Working stroke: 0MM,

4. Working frequency: continuous 100%, intermittent 50%, intermittent 25%, intermittent 5%

5. The insulation grade of enameled wire includes: Class B (130 ℃), Class F (155 ℃) and Class H (180 ℃);

6. The adsorption force sets the ampere-turn value according to the customer's requirements. The greater the suction, the greater the ampere-turn value and the greater the power;

7. Withstand voltage between coil and shell: AC1000 (50/60Hz) 1Sec (leakage current 10mA);

8. Service life: 1 million times on and off, the coil is not burnt, and the working part is not seriously deformed;

9. The terminal wire can withstand a tensile force of 2.0kgf without falling off and breaking;

10. Working temperature: - 5~+95 ℃, 5% RH~85% RH.

11. Electroplating method: copper backing and nickel plating

Precautions for using suction cup electromagnet in Motorcycle Vehicle Accessories:

The sucker-type electromagnet can produce strong adsorption force when it is powered on. It can stop or move the adsorbed object when installed in the automation equipment. It is widely used in automatic distribution production lines, sorting machines, manipulators, test equipment, medical equipment, grinding, cutting and other automatic processing production lines for the transportation, transmission and control of materials or products, which saves power and labor, is safe and reliable, and can be operated remotely.

Precautions for use of brake accessories:

1、 The surface of the adsorbed object should be as flat as possible.

2、 The area of the object to be adsorbed should not be smaller than the electromagnet suction surface.

3、 The adsorbed object must be magnetic conductive material, such as electrical pure iron, low carbon steel, silicon steel sheet, etc.

4、 The adsorbed object must have sufficient thickness (more than 5mm), and generally cannot be less than the wall thickness of the

2. Voltage: 12V 24VDC,

3. Working stroke: 0MM,

4. Working frequency: continuous 100%, intermittent 50%, intermittent 25%, intermittent 5%

5. The insulation grade of enameled wire includes: Class B (130 ℃), Class F (155 ℃) and Class H (180 ℃);

6. The adsorption force sets the ampere-turn value according to the customer's requirements. The greater the suction, the greater the ampere-turn value and the greater the power;

7. Withstand voltage between coil and shell: AC1000 (50/60Hz) 1Sec (leakage current 10mA);

8. Service life: 1 million times on and off, the coil is not burnt, and the working part is not seriously deformed;

9. The terminal wire can withstand a tensile force of 2.0kgf without falling off and breaking;

10. Working temperature: - 5~+95 ℃, 5% RH~85% RH.

11. Electroplating method: copper backing and nickel plating

Precautions for using suction cup electromagnet in Motorcycle Vehicle Accessories:

The sucker-type electromagnet can produce strong adsorption force when it is powered on. It can stop or move the adsorbed object when installed in the automation equipment. It is widely used in automatic distribution production lines, sorting machines, manipulators, test equipment, medical equipment, grinding, cutting and other automatic processing production lines for the transportation, transmission and control of materials or products, which saves power and labor, is safe and reliable, and can be operated remotely.

Precautions for use of brake accessories:

1、 The surface of the adsorbed object should be as flat as possible.

2、 The area of the object to be adsorbed should not be smaller than the electromagnet suction surface.

3、 The adsorbed object must be magnetic conductive material, such as electrical pure iron, low carbon steel, silicon steel sheet, etc.

4、 The adsorbed object must have sufficient thickness (more than 5mm), and generally cannot be less than the wall thickness of the

Related Keywords

Related Keywords