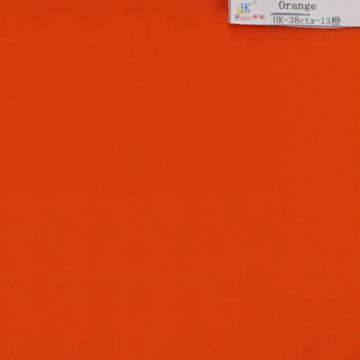

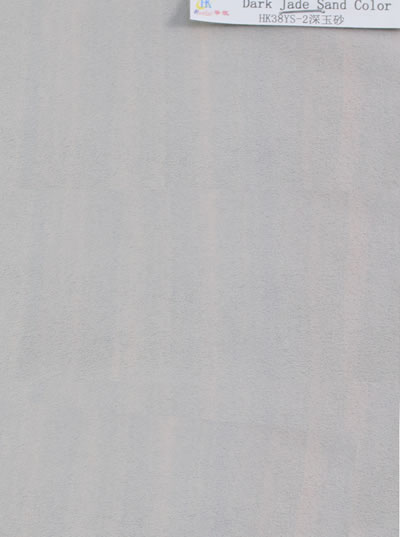

Dark Jade Sand Color HK38YS-2-Color EVA Film

- Transportation:

- Ocean, Air, Express

- Port:

- SHANGHAI;QINGDAO, SHENZHEN;GUANGZHOU, Any Port in China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | T/T,L/C,Paypal |

| Incoterm: | CFR,FOB,CIF,EXW,FAS,FCA,DDP,DDU,Express Delivery,DAF |

| Certificate: | ISO9001;ISO16949;CE;Test Report;SGS;EN;SGCC |

| HS Code: | PVB:3920910001//EVA&SGP:3920109090 |

| Transportation: | Ocean,Air,Express |

| Port: | SHANGHAI;QINGDAO,SHENZHEN;GUANGZHOU,Any Port in China |

BULLET PROOF INTERLAYER DIRECT SELLING, GLASS INTERLAYER FILM DIRECT SELLING, and SAFETY GLASS INTERLAYER FILM DIRECT SELLING are essential components in the production of high-performance laminated glass. These specialized materials serve as the inner layer between two or more panes of glass, providing enhanced strength, security, and protection against impact, shattering, and even ballistic threats. Designed for industrial and commercial applications, these interlayers offer a reliable solution for creating durable and safe glass structures that meet modern safety standards.

The BULLET PROOF INTERLAYER DIRECT SELLING is engineered to withstand extreme forces, making it ideal for use in armored vehicles, secure buildings, and high-risk environments where protection is critical. The GLASS INTERLAYER FILM DIRECT SELLING provides a balance between flexibility and resilience, ensuring that glass remains intact under stress while maintaining optical clarity. The SAFETY GLASS INTERLAYER FILM DIRECT SELLING focuses on reducing the risk of injury from broken glass, offering an added layer of defense in public spaces, schools, and residential areas.

These interlayer solutions are manufactured using advanced polymer technology, allowing for superior adhesion, durability, and resistance to environmental factors such as UV exposure, temperature fluctuations, and moisture. They can be customized to fit specific project requirements, including thickness, color, and transparency, making them suitable for a wide range of applications. Whether used in architectural designs, automotive manufacturing, or security installations, these interlayers contribute to the overall integrity and longevity of laminated glass products.

One of the key advantages of direct selling for BULLET PROOF INTERLAYER, GLASS INTERLAYER FILM, and SAFETY GLASS INTERLAYER FILM is the ability to access high-quality materials at competitive prices without intermediaries. This streamlined approach ensures faster delivery, better customer support, and greater transparency throughout the purchasing process. For businesses looking to enhance their product offerings with reliable and effective interlayer solutions, direct selling offers a cost-effective and efficient alternative to traditional distribution channels.

When selecting an interlayer material, it is important to consider factors such as the intended application, environmental conditions, and performance requirements. BULLET PROOF INTERLAYER is best suited for scenarios requiring maximum protection, while GLASS INTERLAYER FILM and SAFETY GLASS INTERLAYER FILM provide versatile options for different levels of security and functionality. By choosing the right interlayer, manufacturers can ensure that their laminated glass products meet industry standards and exceed customer expectations.

Direct sales of these interlayers also allow for greater control over the supply chain, enabling buyers to work directly with manufacturers to tailor products to their specific needs. This level of customization ensures that each application receives the most appropriate solution, whether it involves creating bullet-resistant glass for government facilities or enhancing the safety of public infrastructure. The ability to source directly from producers also reduces lead times and minimizes the risk of supply disruptions, making it a preferred choice for many industries.

For those involved in the design and production of laminated glass, understanding the benefits of BULLET PROOF INTERLAYER, GLASS INTERLAYER FILM, and SAFETY GLASS INTERLAYER FILM is crucial. These materials not only improve the structural integrity of glass but also play a vital role in protecting people and property. As demand for safer and more resilient building materials continues to grow, the importance of high-quality interlayers becomes increasingly evident.

Whether you are an architect, manufacturer, or installer, incorporating these interlayers into your projects can significantly enhance the performance and reliability of your glass products. With the option to purchase directly from suppliers, you gain access to expert guidance, competitive pricing, and a wide selection of materials designed to meet the highest standards of quality and safety. This direct approach to sourcing interlayers ensures that you receive the best possible value while maintaining the integrity of your final product.

By prioritizing the use of BULLET PROOF INTERLAYER, GLASS INTERLAYER FILM, and SAFETY GLASS INTERLAYER FILM, businesses can create laminated glass that is not only visually appealing but also highly functional and secure. These interlayers are a testament to the advancements in materials science and engineering, offering a reliable solution for a variety of applications across multiple industries. Their widespread adoption highlights their effectiveness in meeting the evolving needs of modern construction and security requirements.

In addition to their structural benefits, these interlayers also contribute to the sustainability of glass products by extending their lifespan and reducing the need for frequent replacements. This makes them an environmentally responsible choice for companies committed to reducing waste and promoting long-term efficiency. As the market for high-performance glass continues to expand, the role of these interlayers will only become more significant, driving innovation and setting new benchmarks in the industry.

Ultimately, the decision to use BULLET PROOF INTERLAYER, GLASS INTERLAYER FILM, and SAFETY GLASS INTERLAYER FILM should be based on a thorough evaluation of your project's requirements and the specific benefits each material offers. Whether you are looking for maximum protection, optimal flexibility, or enhanced safety features, there is an interlayer solution that can meet your needs. With the advantage of direct selling, you can confidently choose the right material for your application, knowing that it has been carefully selected and tested to deliver superior results.

-

PVB film (Polyvinyl Butyral)

-

SGP film (SentryGlas® Polymeric Interlayer)

-

EVA film (Ethylene Vinyl Acetate)

-

Laminated glass interlayer

-

Safety glass film

-

Structural glass interlayer

-

Solar panel encapsulation film

Related Keywords