Milk White HK-103-Color PVB Film

- Transportation:

- Express, Air, Ocean

- Port:

- SHANGHAI;QINGDAO, SHENZHEN;GUANGZHOU, Any Port in China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,Express Delivery,DDU,DDP,DAF |

| Certificate: | ISO9001;ISO16949;CE;Test Report;SGS;EN;SGCC |

| HS Code: | PVB:3920910001//EVA&SGP:3920109090 |

| Transportation: | Express,Air,Ocean |

| Port: | SHANGHAI;QINGDAO,SHENZHEN;GUANGZHOU,Any Port in China |

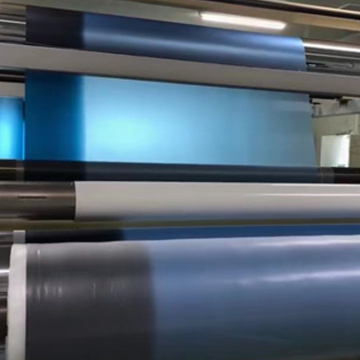

F BLUE PVB FILM, HK-103 PVB Film Color, and F BLUE PVB FILM TECHNICAL are advanced materials designed for high-performance applications in the glass manufacturing industry. These products combine durability, clarity, and aesthetic appeal to meet the demands of modern construction and design projects. Whether you are looking for a transparent, colored, or technically enhanced PVB film, these options provide reliable solutions that cater to both functional and visual requirements.

The F BLUE PVB FILM is a specialized variant that offers a unique blue tint while maintaining excellent adhesion properties and optical clarity. This makes it ideal for applications where color differentiation and UV protection are essential. The HK-103 PVB Film Color is another premium choice, known for its vibrant hues and resistance to fading, ensuring long-lasting performance even under prolonged exposure to sunlight. Meanwhile, the F BLUE PVB FILM TECHNICAL is engineered with advanced chemical compositions to enhance impact resistance, sound insulation, and overall structural integrity of laminated glass products.

Key features of these PVB films include superior flexibility, strong bonding capabilities, and compatibility with various types of glass. They are manufactured using high-quality raw materials and undergo rigorous quality control processes to ensure consistency and reliability. The films are also designed to withstand extreme weather conditions, making them suitable for use in both indoor and outdoor environments. Additionally, their low maintenance requirements contribute to cost-effectiveness over time.

Each product is tailored to specific needs within the architectural and automotive sectors. The F BLUE PVB FILM is often used in decorative glass panels, sunrooms, and custom glass installations where a distinct color is desired without compromising transparency. The HK-103 PVB Film Color finds application in commercial buildings, residential windows, and signage where visual appeal is a priority. The F BLUE PVB FILM TECHNICAL, on the other hand, is preferred in safety-critical areas such as skylights, windshields, and security glazing due to its enhanced strength and durability.

These PVB films are versatile and can be customized to fit different thicknesses and dimensions based on project specifications. Their seamless integration with laminated glass ensures a smooth finish and improved aesthetics. Moreover, they contribute to energy efficiency by reducing heat transfer and glare, thereby enhancing the comfort of interior spaces. The technical specifications of the F BLUE PVB FILM TECHNICAL further support its use in high-performance applications where precision and reliability are paramount.

Users have reported positive experiences with these products, highlighting their ease of installation, consistent quality, and long-term performance. Many professionals in the construction and design industries rely on these PVB films for their ability to deliver both practical benefits and visual enhancements. The combination of functionality and style makes them a popular choice among architects, engineers, and manufacturers seeking innovative glass solutions.

When considering the use of F BLUE PVB FILM, HK-103 PVB Film Color, or F BLUE PVB FILM TECHNICAL, it is important to evaluate the specific requirements of the project. Factors such as environmental exposure, structural demands, and aesthetic preferences should be taken into account. Consulting with experienced suppliers or manufacturers can help determine the most suitable option for each application. Proper handling and storage of these films are also crucial to maintain their integrity and performance over time.

Common questions about these products often revolve around their compatibility with different types of glass, their resistance to temperature fluctuations, and their ability to meet industry standards. Some users may also inquire about the availability of samples or the possibility of custom orders. Understanding the technical data sheets and specifications provided by the manufacturer can offer valuable insights into the performance characteristics of each product. Additionally, staying informed about advancements in PVB technology can help users make well-informed decisions when selecting materials for their projects.

-

PVB film (Polyvinyl Butyral)

-

SGP film (SentryGlas® Polymeric Interlayer)

-

EVA film (Ethylene Vinyl Acetate)

-

Laminated glass interlayer

-

Safety glass film

-

Structural glass interlayer

-

Solar panel encapsulation film

Related Keywords