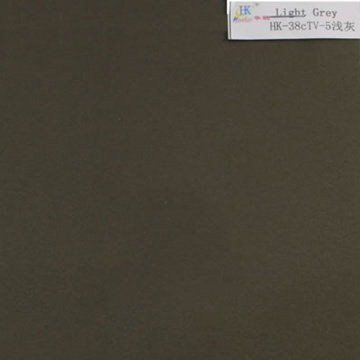

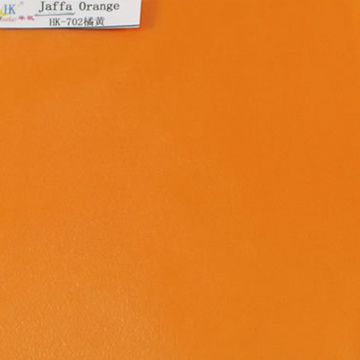

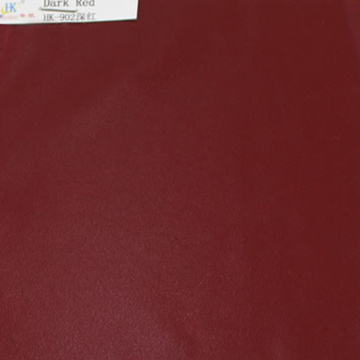

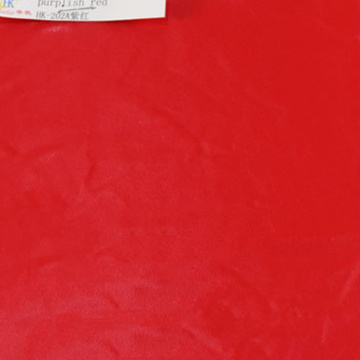

Bright Red HK-202-Color PVB Film

- Transportation:

- Ocean, Air, Express

- Port:

- SHANGHAI;QINGDAO, SHENZHEN;GUANGZHOU, Any Port in China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDU,DDP,Express Delivery,DAF |

| Certificate: | ISO9001;ISO16949;CE;Test Report;SGS;EN;SGCC |

| HS Code: | PVB:3920910001//EVA&SGP:3920109090 |

| Transportation: | Ocean,Air,Express |

| Port: | SHANGHAI;QINGDAO,SHENZHEN;GUANGZHOU,Any Port in China |

Safety Glass Interlayer Film Trade, Laminated Glass Interlayer Film Trade, and PVB Film Trade are essential components in the production of durable and secure glass products. These interlayer films serve as the critical bonding material between two or more layers of glass, ensuring enhanced safety, strength, and optical clarity. Whether used in automotive, architectural, or industrial applications, these films play a vital role in meeting global standards for quality and performance. The use of high-quality interlayer films not only improves the structural integrity of laminated glass but also provides additional benefits such as sound insulation, UV protection, and impact resistance.

The Safety Glass Interlayer Film Trade refers to the commercial exchange of materials designed to prevent glass from shattering into sharp pieces upon impact. This type of film is commonly used in windshields, side windows, and rear windows of vehicles, offering superior protection against injuries. Similarly, the Laminated Glass Interlayer Film Trade involves the supply and distribution of materials that enhance the durability of multi-layered glass structures. These films are often made from polyvinyl butyral (PVB), which is known for its excellent adhesion properties and ability to absorb energy during collisions. The PVB Film Trade specifically focuses on the sourcing, manufacturing, and selling of PVB-based interlayers, which are widely used across various industries due to their reliability and versatility.

Key features of these interlayer films include their high tensile strength, excellent transparency, and resistance to environmental factors such as moisture, heat, and UV radiation. They are available in different thicknesses and formulations to suit specific application requirements. For instance, automotive-grade PVB films are engineered to withstand extreme temperatures and provide optimal visibility, while architectural-grade films offer enhanced security and aesthetic appeal. Additionally, these films can be customized with special additives to improve acoustic performance, reduce glare, or increase thermal insulation. The overall goal of using these materials is to create safer, more resilient, and visually appealing glass products that meet international safety regulations.

In the context of the Safety Glass Interlayer Film Trade, suppliers and manufacturers must adhere to strict quality control measures to ensure consistency and compliance with industry standards. This includes rigorous testing for adhesion, flexibility, and chemical resistance. The Laminated Glass Interlayer Film Trade also emphasizes the importance of proper installation techniques to maximize the effectiveness of the interlayer. Professionals involved in this trade often require specialized training to handle and apply the films correctly, ensuring that the final product performs as intended. The PVB Film Trade, being a subset of the broader interlayer film market, is influenced by factors such as raw material availability, technological advancements, and evolving consumer demands. As the demand for safer and more sustainable building materials continues to grow, the significance of these films in the global market is expected to increase.

The use of Safety Glass Interlayer Film Trade, Laminated Glass Interlayer Film Trade, and PVB Film Trade extends beyond traditional applications. In the automotive sector, these films are crucial for producing impact-resistant windshields and side windows, significantly reducing the risk of injury in accidents. In the construction industry, they are used in safety glazing for buildings, providing an added layer of protection against break-ins, natural disasters, and accidental impacts. Industrial applications include the manufacturing of protective barriers, display cases, and machine guards, where the combination of strength and clarity is essential. Moreover, these films are increasingly being integrated into smart glass technologies, enabling features such as variable tinting and energy efficiency. As the need for safer and more functional glass solutions continues to rise, the role of these interlayer films becomes even more prominent.

Customer feedback highlights the reliability and effectiveness of these interlayer films in real-world scenarios. Many users have reported improved safety and durability in their glass products after incorporating these materials. Some have noted significant reductions in noise levels, making them ideal for use in urban environments or near busy roads. Others have praised the aesthetic qualities of the finished products, emphasizing the clear and distortion-free appearance provided by high-quality interlayers. Additionally, professionals in the field have shared their experiences regarding the ease of handling and application, further reinforcing the value of these materials. Overall, the positive reception from end-users and industry experts underscores the importance of these films in modern glass manufacturing processes.

Common questions about the Safety Glass Interlayer Film Trade, Laminated Glass Interlayer Film Trade, and PVB Film Trade often revolve around the selection process, installation methods, and maintenance requirements. One frequently asked question is how to choose the right type of interlayer film for a specific application. The answer typically depends on factors such as the intended use, environmental conditions, and desired performance characteristics. Another common inquiry is about the best practices for applying the film, which may involve using specialized tools and following manufacturer guidelines to ensure proper adhesion and alignment. Maintenance tips usually focus on cleaning procedures and avoiding exposure to harsh chemicals that could degrade the film over time. Users also ask about the lifespan of these materials, with most sources indicating that high-quality interlayer films can last for many years without significant deterioration. By addressing these concerns, potential buyers can make informed decisions and achieve optimal results when using these products.

Bright Red HK-202-Color PVB Film ,SAFETY GLASS INTERLAYER FILM TRADE

Related Keywords