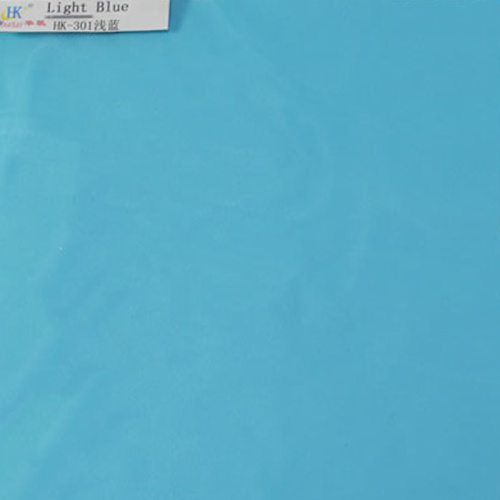

Light Blue HK-301-Color PVB Film

- Transportation:

- Ocean, Air, Express

- Port:

- SHANGHAI;QINGDAO, SHENZHEN;GUANGZHOU, Any Port in China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,Express Delivery,DDU,DAF,DDP |

| Certificate: | ISO9001;ISO16949;CE;Test Report;SGS;EN;SGCC |

| HS Code: | PVB:3920910001//EVA&SGP:3920109090 |

| Transportation: | Ocean,Air,Express |

| Port: | SHANGHAI;QINGDAO,SHENZHEN;GUANGZHOU,Any Port in China |

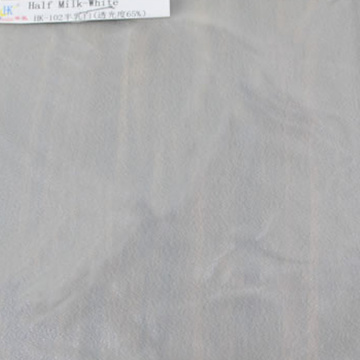

Porcelain White PVB Film, Super Milk White PVB Film, and Automotive PVB Film Trade are essential components in the modern automotive and architectural industries. These specialized films offer a combination of aesthetic appeal, durability, and functional performance that meets the demands of today's market. Whether you are looking for a solution to enhance the visual appearance of glass or improve safety and insulation, these products provide a reliable and high-quality option.

The Porcelain White PVB Film is known for its elegant, smooth surface that mimics the look of porcelain. This film is ideal for applications where a clean, white finish is desired without compromising on clarity or strength. It is often used in laminated glass for both interior and exterior applications, offering an attractive alternative to traditional clear or tinted films. The Super Milk White PVB Film, on the other hand, provides a softer, more opaque white finish that can help reduce glare and improve privacy while maintaining a modern and sophisticated appearance. Both types of PVB films are designed to be compatible with standard lamination processes, making them easy to integrate into existing manufacturing workflows.

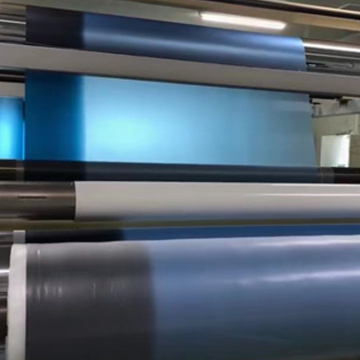

The Automotive PVB Film Trade refers to the global exchange of these materials, which are widely used in the production of windshields, side windows, and rear windows for vehicles. These films are critical in ensuring the structural integrity and safety of automotive glass. They also contribute to noise reduction, UV protection, and energy efficiency, making them a valuable addition to any vehicle. As the automotive industry continues to evolve, the demand for high-performance PVB films has increased, driving innovation and expansion in the trade sector.

One of the key features of these PVB films is their ability to bond effectively with glass under heat and pressure. This ensures a strong, durable connection that can withstand various environmental conditions. Additionally, they are resistant to yellowing, cracking, and peeling, which helps maintain the appearance and functionality of the finished product over time. The films also offer excellent optical clarity, allowing for clear visibility while adding a layer of protection against impact and shattering.

In terms of customization, both Porcelain White and Super Milk White PVB Films can be produced in different thicknesses and sizes to suit specific project requirements. This flexibility makes them suitable for a wide range of applications, from residential and commercial buildings to high-end automotive designs. The Automotive PVB Film Trade supports this versatility by providing a variety of options to meet the diverse needs of manufacturers and suppliers around the world.

The use of these PVB films extends beyond just aesthetics. They play a crucial role in enhancing the safety and comfort of vehicles and structures. For example, in automotive applications, PVB films help prevent glass shards from scattering in the event of a collision, reducing the risk of injury. In architectural settings, they contribute to energy efficiency by blocking harmful UV rays and reducing heat transfer. These benefits make them a popular choice among architects, designers, and vehicle manufacturers who prioritize both form and function.

When it comes to installation, these PVB films are designed to work seamlessly with standard lamination techniques. This means that they can be easily applied during the manufacturing process without requiring additional equipment or modifications. Their compatibility with existing systems makes them a cost-effective and efficient solution for those looking to upgrade their glass products. Furthermore, their long-lasting performance reduces the need for frequent replacements, offering a sustainable and economical choice in the long run.

For those involved in the Automotive PVB Film Trade, understanding the properties and benefits of these materials is essential. They not only serve as critical components in vehicle manufacturing but also represent a growing market with significant potential for growth. As more companies seek to improve the quality and performance of their products, the demand for high-grade PVB films is expected to continue rising. This trend highlights the importance of staying informed about the latest developments in the industry and exploring new opportunities for collaboration and innovation.

Users have reported positive experiences with these PVB films, noting their ease of application, durability, and visual appeal. Many have praised the ability of the Porcelain White and Super Milk White varieties to enhance the look of their projects without sacrificing performance. In the automotive sector, the reliability and safety benefits of PVB films have been widely recognized, leading to increased adoption across different vehicle models and brands.

Despite their many advantages, there are some considerations to keep in mind when working with these materials. Proper storage and handling are important to ensure optimal performance and longevity. Additionally, it is recommended to follow manufacturer guidelines for installation and maintenance to avoid any issues that may arise from improper use. By taking these steps, users can maximize the value and effectiveness of their PVB film investments.

Overall, Porcelain White PVB Film, Super Milk White PVB Film, and Automotive PVB Film Trade represent a valuable and versatile solution for a wide range of applications. Whether you are looking to enhance the appearance of your glass products or improve the safety and efficiency of your vehicles, these materials offer a reliable and high-quality option. With their growing popularity and expanding market presence, they are sure to remain a key component in the future of both the automotive and architectural industries.

-

PVB film (Polyvinyl Butyral)

-

SGP film (SentryGlas® Polymeric Interlayer)

-

EVA film (Ethylene Vinyl Acetate)

-

Laminated glass interlayer

-

Safety glass film

-

Structural glass interlayer

-

Solar panel encapsulation film

Related Keywords