HK-K306 Sky Blue-Color PVB Film

- Transportation:

- Ocean, Express, Air

- Port:

- SHANGHAI;QINGDAO, SHENZHEN;GUANGZHOU, Any Port in China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDP,Express Delivery,DAF,DDU |

| Certificate: | ISO9001;ISO16949;CE;Test Report;SGS;EN;SGCC |

| HS Code: | PVB:3920910001//EVA&SGP:3920109090 |

| Transportation: | Ocean,Express,Air |

| Port: | SHANGHAI;QINGDAO,SHENZHEN;GUANGZHOU,Any Port in China |

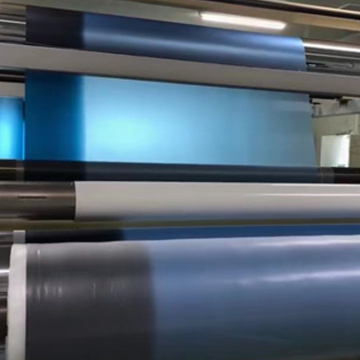

EXTRA CLEAR PVB FILM HIGH-QUALITY, ULTRA CLEAR PVB FILM HIGH-QUALITY, and SUPER CLEAR PVB FILM HIGH-QUALITY are premium materials designed for applications where visual clarity and structural integrity are essential. These advanced films are crafted with precision to deliver exceptional transparency, durability, and resistance to environmental factors. Whether used in architectural glazing, automotive components, or safety glass manufacturing, these products provide a reliable solution that meets the highest industry standards.

The EXTRACLEAR PVB FILM HIGH-QUALITY is ideal for those seeking superior optical performance without compromising on strength. Its ultra-clear variant, ULTRA CLEAR PVB FILM HIGH-QUALITY, offers even greater light transmission and minimal distortion, making it suitable for high-end display systems and decorative glass applications. The SUPER CLEAR PVB FILM HIGH-QUALITY further enhances this by incorporating enhanced UV protection and improved adhesion properties, ensuring long-term performance in demanding environments.

Key features of these high-quality PVB films include exceptional clarity, excellent impact resistance, and strong bonding capabilities when laminated between glass panes. They are also resistant to moisture, heat, and chemical exposure, making them suitable for both indoor and outdoor use. The advanced formulation ensures that each layer remains stable over time, reducing the risk of yellowing, delamination, or cracking. These characteristics make them a preferred choice for professionals in the construction, automotive, and design industries.

When it comes to detailed description, the EXTRACLEAR PVB FILM HIGH-QUALITY is manufactured using state-of-the-art technology to ensure uniform thickness and consistent quality across all production batches. This level of precision guarantees that the final product performs reliably under various conditions. The ULTRA CLEAR PVB FILM HIGH-QUALITY builds upon this foundation by optimizing the material’s refractive index, resulting in a nearly imperceptible appearance when used in multi-layered glass assemblies. The SUPER CLEAR PVB FILM HIGH-QUALITY takes this a step further by integrating additives that improve its thermal stability and UV resistance, making it particularly effective in regions with intense sunlight exposure.

These high-performance PVB films find their place in a wide range of applications. In architectural settings, they are used to create safety glass for windows, doors, and partitions, offering both aesthetic appeal and protection against breakage. In the automotive sector, they are essential for windshields and side windows, providing drivers with clear visibility and added safety. For custom glass projects, such as signage, display cases, and artistic installations, these films allow for creative expression while maintaining structural integrity. Their versatility makes them an indispensable component in modern design and engineering solutions.

User feedback consistently highlights the benefits of using these high-quality PVB films. Many professionals praise the clarity and durability, noting that the films maintain their performance over extended periods. Customers in the construction and automotive industries often mention how the films contribute to the overall safety and longevity of their projects. Some users have also appreciated the ease of application and the ability to achieve a seamless finish when laminated with glass. Overall, the positive experiences reflect the reliability and effectiveness of these products in real-world scenarios.

Common questions about these high-quality PVB films often revolve around their suitability for different types of glass and environmental conditions. Users frequently ask whether the films can be used in extreme climates, to which the answer is yes—due to their resistance to temperature fluctuations and UV degradation. Another common inquiry concerns the compatibility of these films with various lamination processes, including both dry and wet methods. It is also important to note that these films are available in multiple thicknesses, allowing for customization based on specific project requirements. Additionally, many users seek guidance on storage and handling to ensure optimal performance during installation.

-

PVB film (Polyvinyl Butyral)

-

SGP film (SentryGlas® Polymeric Interlayer)

-

EVA film (Ethylene Vinyl Acetate)

-

Laminated glass interlayer

-

Safety glass film

-

Structural glass interlayer

-

Solar panel encapsulation film

Related Keywords