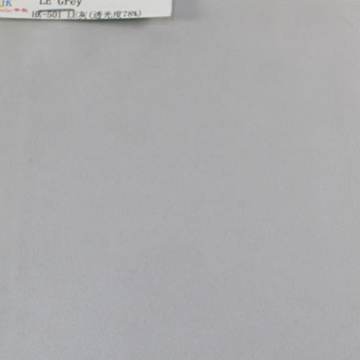

HK-H201 Milky White-Color PVB Film

- Transportation:

- Ocean, Air, Express

- Port:

- SHANGHAI;QINGDAO, SHENZHEN;GUANGZHOU, Any Port in China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,DDU,DDP,Express Delivery,DAF |

| Certificate: | ISO9001;ISO16949;CE;Test Report;SGS;EN;SGCC |

| HS Code: | PVB:3920910001//EVA&SGP:3920109090 |

| Transportation: | Ocean,Air,Express |

| Port: | SHANGHAI;QINGDAO,SHENZHEN;GUANGZHOU,Any Port in China |

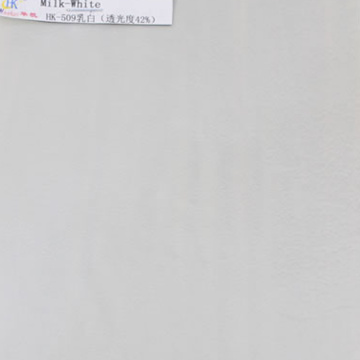

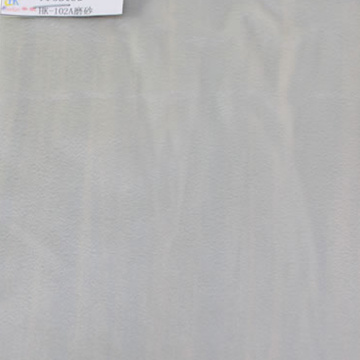

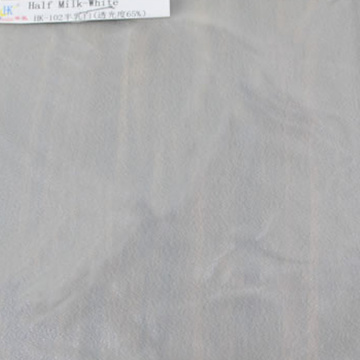

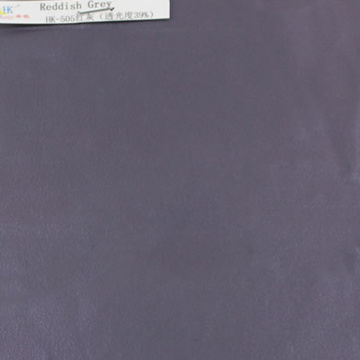

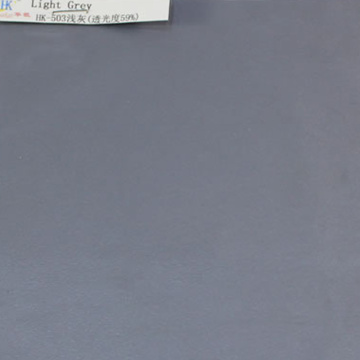

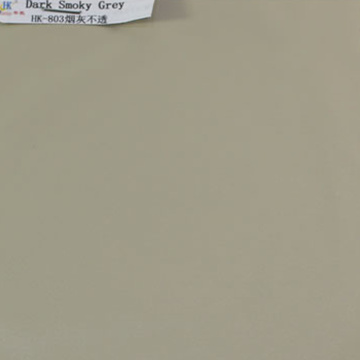

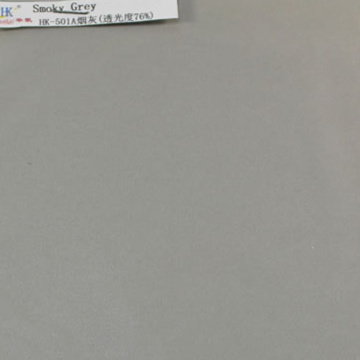

Color PVB Film High-Quality, PVB Interlayer Film High-Quality, and Glass Interlayer Film for Autoclave High-Quality are premium materials designed for advanced laminated glass applications. These films offer superior performance, durability, and aesthetic appeal, making them ideal for use in automotive, architectural, and industrial sectors. Whether you're looking to enhance the safety of your vehicle's windshield or create visually striking glass panels for commercial buildings, these high-quality interlayers provide the reliability and precision required for demanding environments.

The Color PVB Film High-Quality is specifically engineered to deliver vibrant and consistent coloration while maintaining the structural integrity of laminated glass. This makes it an excellent choice for custom glass designs, decorative windows, and specialty automotive glazing. The PVB Interlayer Film High-Quality ensures strong adhesion between glass panes, preventing delamination even under extreme conditions. Its exceptional clarity and UV resistance help protect interiors from fading and damage, enhancing both functionality and visual appeal.

The Glass Interlayer Film for Autoclave High-Quality is a specialized product designed for use in autoclave processes, where high pressure and temperature are applied to bond glass layers together. This film offers excellent flowability, ensuring uniform distribution during lamination and minimizing air bubbles or imperfections. It is formulated to withstand the rigorous conditions of industrial production, delivering consistent results across large-scale manufacturing operations.

One of the key features of these high-quality PVB films is their ability to absorb impact energy, significantly reducing the risk of shattering upon collision. This makes them an essential component in automotive safety glass, such as windshields and side windows. Additionally, their flexibility allows for complex shaping and molding, enabling the creation of curved and contoured glass elements without compromising strength or clarity.

The durability of these interlayer films is further enhanced by their resistance to moisture, chemicals, and environmental stressors. This ensures long-term performance and minimizes the need for frequent replacements, offering cost-effective solutions for manufacturers and end-users alike. Their compatibility with various types of glass, including tempered, annealed, and laminated glass, adds to their versatility and broadens their application scope.

In terms of technical specifications, these films are available in a range of thicknesses and colors to suit different requirements. They meet international standards for safety, quality, and performance, ensuring compliance with industry regulations. Their ease of handling and processing makes them suitable for both small-scale projects and large-scale production lines, providing flexibility for diverse applications.

These high-quality PVB films are widely used in the automotive industry for manufacturing windshields, side windows, and rear windows that offer enhanced safety and comfort. In the architectural sector, they are employed in the production of safety glass for doors, partitions, and facades, contributing to the overall aesthetics and structural integrity of buildings. Industrial applications include the creation of protective glass panels, display cases, and other specialized components that require both strength and visual appeal.

Users have consistently praised the performance and reliability of these high-quality PVB films. Many report improved safety and durability in their glass products, along with better color consistency and clarity. The seamless integration into existing manufacturing processes has also been highlighted as a major advantage, allowing for efficient and cost-effective production.

When considering the use of Color PVB Film High-Quality, PVB Interlayer Film High-Quality, or Glass Interlayer Film for Autoclave High-Quality, it is important to select a supplier that provides reliable quality assurance and technical support. Choosing the right material can make a significant difference in the final outcome, ensuring that the end product meets the highest standards of performance and appearance.

For those seeking a dependable and high-performance solution for laminated glass applications, these PVB films offer a proven and trusted option. Their combination of strength, clarity, and versatility makes them a valuable asset in a wide range of industries. Whether you are a manufacturer, designer, or installer, investing in high-quality PVB interlayers can lead to better results and greater customer satisfaction.

Overall, the Color PVB Film High-Quality, PVB Interlayer Film High-Quality, and Glass Interlayer Film for Autoclave High-Quality represent the pinnacle of innovation and excellence in the field of laminated glass technology. Their advanced properties and broad applicability ensure that they remain a preferred choice for professionals who demand the best in performance and reliability.

-

PVB film (Polyvinyl Butyral)

-

SGP film (SentryGlas® Polymeric Interlayer)

-

EVA film (Ethylene Vinyl Acetate)

-

Laminated glass interlayer

-

Safety glass film

-

Structural glass interlayer

-

Solar panel encapsulation film

Related Keywords