EVA film ( Solar )-EVA Film (High-End)

- Transportation:

- Ocean, Air, Express

- Port:

- SHANGHAI;QINGDAO, SHENZHEN;GUANGZHOU, Any Port in China

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Payment Type: | L/C,T/T,Paypal |

| Incoterm: | FOB,CIF,CFR,EXW,FAS,FCA,Express Delivery,DDU,DDP,DAF |

| Certificate: | ISO9001;ISO16949;CE;Test Report;SGS;EN;SGCC |

| HS Code: | PVB:3920910001//EVA&SGP:3920109090 |

| Transportation: | Ocean,Air,Express |

| Port: | SHANGHAI;QINGDAO,SHENZHEN;GUANGZHOU,Any Port in China |

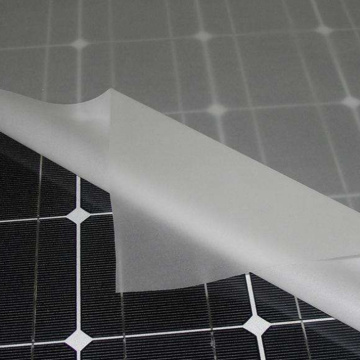

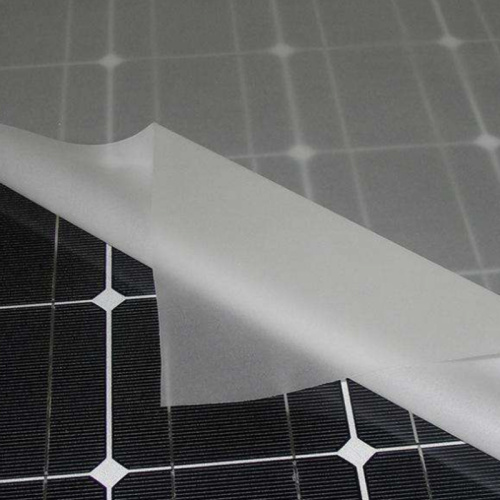

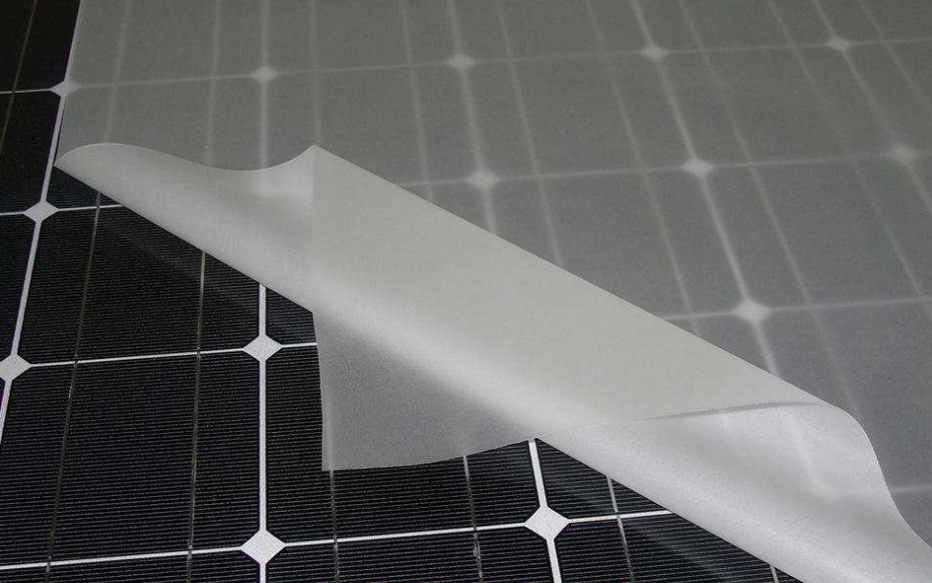

EVA film ( Solar )-EVA Film (High-End)

1. HK-H Solar EVA film

Huakai Solar EVA encapsulation film is a three-dimensional network structure formed by extrusion-casting of EVA resin (ethylene-vinyl acetate copolymer) and extrusion-casting of EVA encapsulation film under certain temperature and pressure. High-strength materials are used in solar cell modules.

Product Features:

More than 90% transmittance

Suitable degree of crosslinking

Good durability, UV resistance, heat resistance and humidity resistance

Great bonding strength with glass and back sheet materials

Low shrinkage in lamination

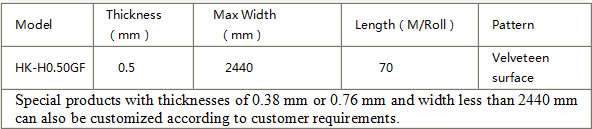

Product models and specifications

Lamination thermosetting process conditions

Equipment: Solar PV module laminating machine

1. Due to the difference in structural performance of the laminator, the process conditions used will not be the same.

2, the working environment temperature of the laminating machine (the difference between winter and summer) will cause different working temperature of the lamination.

3. The user must first make a sample to determine the correct lamination curing process conditions and ensure the quality of the mass-produced products.

The appearance quality of the product

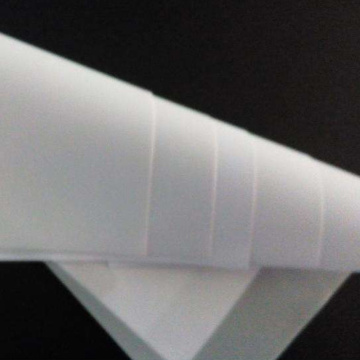

1. Appearance: translucent, flat appearance, neat end face, no stains

2,Thickness: HK-H0.50GF thickness tolerance: ± 0.02MM

3. Width: HK-H0.50GF width tolerance: 2100+25/-0MM

4,Length: HK-H0.50GF tolerance of per roll : +1M/-0M

Storage conditions

The product should be stored in a dry place indoors to avoid direct sunlight. The indoor temperature is controlled at 5 °C-30 °C, the corresponding humidity is less than 60%, and it should not be close to the heating equipment and dusty environment. The film can not be stacked to avoid causing adhesion.

Storage time

Under the right storage conditions, the effective storage period is no more than 4 months from the date of production. Once the film is unpacked, the remaining film should be protected from dust, moisture, sun, and used up within one week.

Storage method

Avoid sun, rain, fire, hard collision, free from pollution of the transportation environment and open storage. Do not let the product packaging damaged and stacking adhesion.

-

PVB film (Polyvinyl Butyral)

-

SGP film (SentryGlas® Polymeric Interlayer)

-

EVA film (Ethylene Vinyl Acetate)

-

Laminated glass interlayer

-

Safety glass film

-

Structural glass interlayer

-

Solar panel encapsulation film

Related Keywords