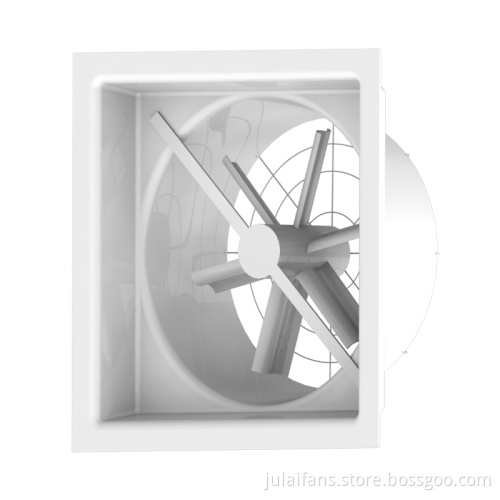

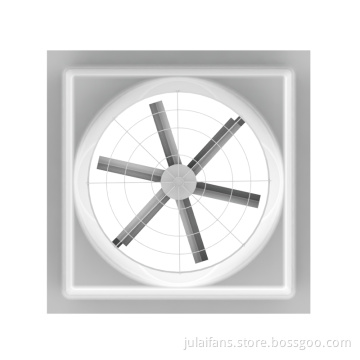

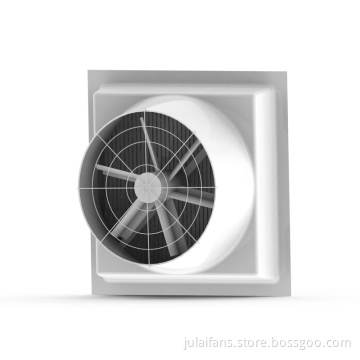

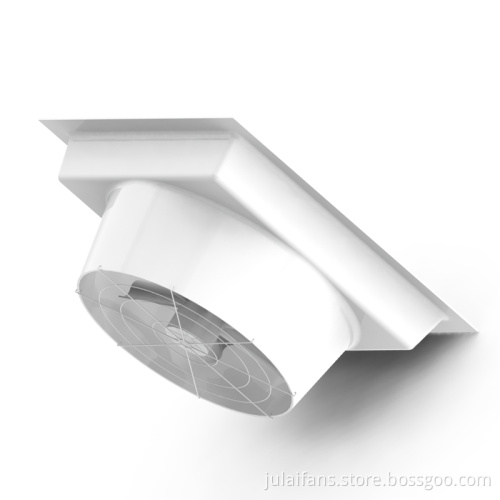

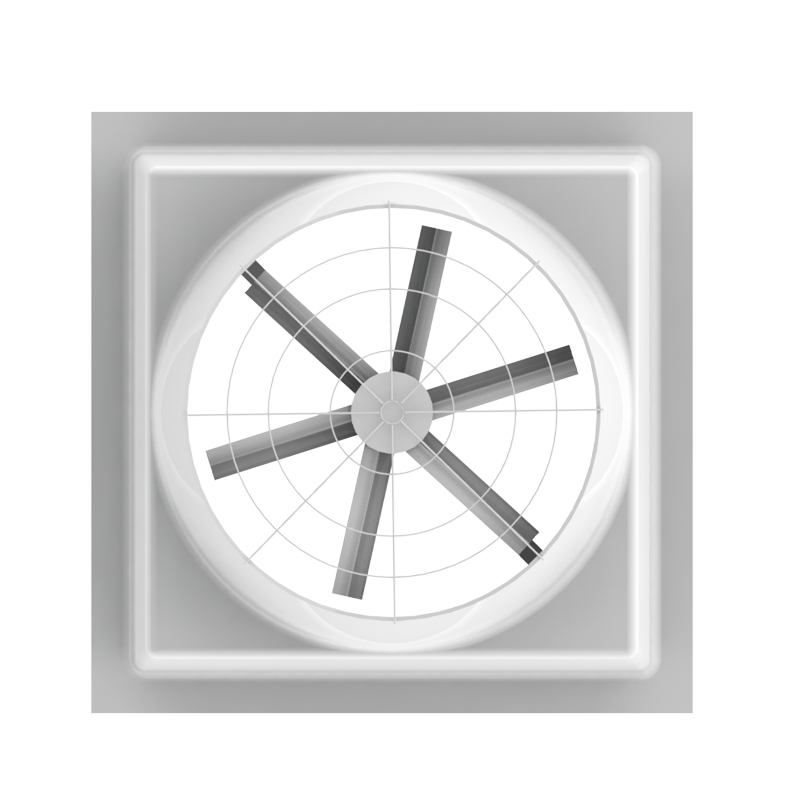

ventilation negative pressure fan equipment

-

$113.42≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- chongqing, Cuntan

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 1000 Set/Sets per Month |

| Supply Ability: | 1000 Set/Sets per Month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land |

| Port: | chongqing,Cuntan |

Product Description

Product Description

Can negative pressure fan solve the problem of stuffiness in factories?

In summer, poorly ventilated factories are particularly stuffy, and ventilation and cooling problems can be solved simultaneously, making it the best choice for modern factories to cool and ventilate. HVLS fans and negative pressure fan can effectively solve the problem of stuffiness in the factory building.

In practical applications, the air forms a convective blow from the air inlet to the negative pressure fan. The air flows into the workshop in an orderly manner from the air inlet, flows through the workshop, and is discharged from the workshop by the negative pressure fan. The air exchange is thorough and efficient, and the air exchange rate can reach up to 99%. The cooling advantage is obvious.

In summer, there are obvious high temperature problems in the workshop. Choosing negative pressure fan for ventilation and cooling in the workshop has the characteristics of low investment cost, large air volume, low noise, low energy consumption, stable operation, long service life, and high efficiency.

For the current use of cooling equipment, negative pressure fan are not only efficient but also energy-saving and environmentally friendly. However, the installation of negative pressure fan with obvious cooling effects is also crucial.

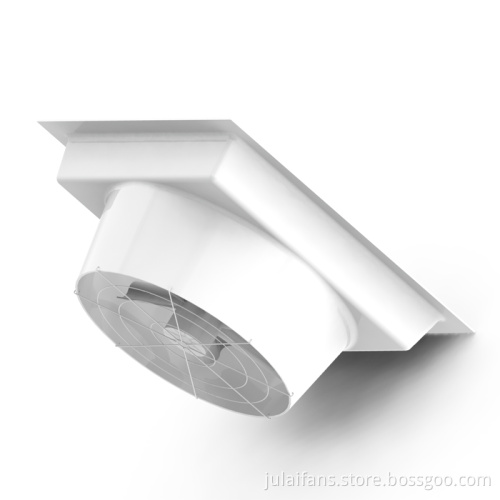

Industrial fans can be installed on outdoor floors, walls, or roofs, but the installation environment must ensure smooth and fresh air, and cannot be installed at exhaust outlets with foul or odorous gases. Generally speaking, it is best to choose to install negative pressure fan in the middle of the building to minimize the supply resistance of the air duct and shorten the length of the installation pipeline; If possible, install the negative pressure fan in the dominant wind direction of the cooling environment as much as possible.

If installed indoors, the air supply duct must match the model of the negative pressure fan, and suitable air supply ducts should be designed according to the actual installation environment and the number of air outlets. In addition, when installing negative pressure fans, attention should be paid to sealing and waterproofing the pipes between indoor and outdoor to avoid rainwater leakage. At the installation position of the negative pressure fan, it is necessary to ensure that its frame structure can support the weight of the entire negative pressure fan body, the air supply pipeline at the machine outlet, and maintenance personnel.

In summer, poorly ventilated factories are particularly stuffy, and ventilation and cooling problems can be solved simultaneously, making it the best choice for modern factories to cool and ventilate. HVLS fans and negative pressure fan can effectively solve the problem of stuffiness in the factory building.

In practical applications, the air forms a convective blow from the air inlet to the negative pressure fan. The air flows into the workshop in an orderly manner from the air inlet, flows through the workshop, and is discharged from the workshop by the negative pressure fan. The air exchange is thorough and efficient, and the air exchange rate can reach up to 99%. The cooling advantage is obvious.

In summer, there are obvious high temperature problems in the workshop. Choosing negative pressure fan for ventilation and cooling in the workshop has the characteristics of low investment cost, large air volume, low noise, low energy consumption, stable operation, long service life, and high efficiency.

For the current use of cooling equipment, negative pressure fan are not only efficient but also energy-saving and environmentally friendly. However, the installation of negative pressure fan with obvious cooling effects is also crucial.

Industrial fans can be installed on outdoor floors, walls, or roofs, but the installation environment must ensure smooth and fresh air, and cannot be installed at exhaust outlets with foul or odorous gases. Generally speaking, it is best to choose to install negative pressure fan in the middle of the building to minimize the supply resistance of the air duct and shorten the length of the installation pipeline; If possible, install the negative pressure fan in the dominant wind direction of the cooling environment as much as possible.

If installed indoors, the air supply duct must match the model of the negative pressure fan, and suitable air supply ducts should be designed according to the actual installation environment and the number of air outlets. In addition, when installing negative pressure fans, attention should be paid to sealing and waterproofing the pipes between indoor and outdoor to avoid rainwater leakage. At the installation position of the negative pressure fan, it is necessary to ensure that its frame structure can support the weight of the entire negative pressure fan body, the air supply pipeline at the machine outlet, and maintenance personnel.

Related Keywords

Related Keywords