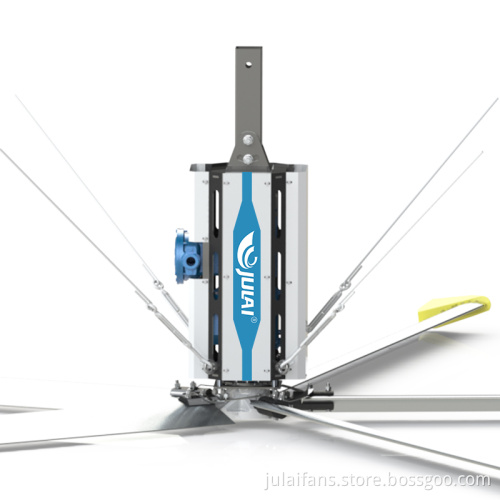

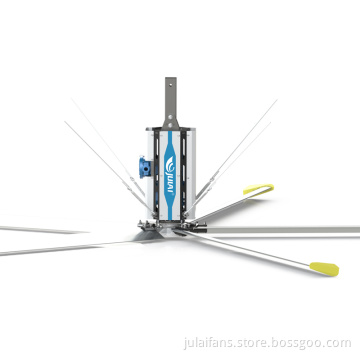

Large industrial ceiling fan with large air volume

-

$2685.001-3 Set/Sets

-

$2675.004-10 Set/Sets

-

$2665.00≥11 Set/Sets

- Transportation:

- Ocean, Land

- Port:

- chongqing, Cuntan

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 1000 Set/Sets per Month |

| Supply Ability: | 1000 Set/Sets per Month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land |

| Port: | chongqing,Cuntan, |

Product Description

Product Description

It has always been difficult to maintain comfort for personnel in large factories or storage spaces. Traditional heating and cooling methods not only fail to work, but also cause increased energy costs. Vertical fans and traditional ceiling fans cannot achieve the desired results. The successful use of HVLS fans in large warehouses is the concrete realization of this vision. HVLS fans can improve personnel comfort Improving indoor environment and safety meets the needs of various industries such as modern logistics and warehousing.

Advantages of industrial fans: low investment, low operating cost, and simplicity. Ceiling fans and floor fans are collectively referred to as fans. At this stage, they are still one of the cooling methods used in many workshops and plants. A large number of fans are arranged in the post area to blow people, achieving a cooling effect. However, fans do not essentially change the temperature of the environment, and do not have a good effect in a stuffy workshop. The same principle applies to the so-called large industrial ceiling fans nowadays. If indoor air is not circulated and pure agitation does not have a good effect.

The cooling water curtain system for cooling and ventilation in the workshop cools the air outside the workshop by secondary cooling. The environmentally friendly air conditioner for cooling and ventilation in the workshop cools the air outside the workshop and then sends it into the workshop for cooling. An environmental friendly air conditioner is installed on the exterior wall of the workshop, which supplies air to the workshop through a fan. After the outdoor fresh air flows through the wet curtain soaked in water, the air fully contacts with water and absorbs sensible heat in the air, thereby achieving the goals of cooling, ventilation, dust removal, and increasing the oxygen content of the air in the workshop. This scheme is particularly suitable for high temperature and crowded places. The industrial fan for cooling and ventilation in the workshop provides ventilation, cooling and ventilation, drying and dehumidification, cool in spring and autumn, and comfortable in summer and winter. The airflow generated by the rotation of the high pressure fan in the workshop and warehouse forms a cone from top to bottom and is pushed towards the ground. After reaching the ground, it flows in a horizontal direction. When encountering side barriers or horizontal airflow adjacent to the fan, it is pushed upward to the roof, thereby enhancing the air circulation in all directions and from multiple angles.

Advantages of industrial fans: low investment, low operating cost, and simplicity. Ceiling fans and floor fans are collectively referred to as fans. At this stage, they are still one of the cooling methods used in many workshops and plants. A large number of fans are arranged in the post area to blow people, achieving a cooling effect. However, fans do not essentially change the temperature of the environment, and do not have a good effect in a stuffy workshop. The same principle applies to the so-called large industrial ceiling fans nowadays. If indoor air is not circulated and pure agitation does not have a good effect.

The cooling water curtain system for cooling and ventilation in the workshop cools the air outside the workshop by secondary cooling. The environmentally friendly air conditioner for cooling and ventilation in the workshop cools the air outside the workshop and then sends it into the workshop for cooling. An environmental friendly air conditioner is installed on the exterior wall of the workshop, which supplies air to the workshop through a fan. After the outdoor fresh air flows through the wet curtain soaked in water, the air fully contacts with water and absorbs sensible heat in the air, thereby achieving the goals of cooling, ventilation, dust removal, and increasing the oxygen content of the air in the workshop. This scheme is particularly suitable for high temperature and crowded places. The industrial fan for cooling and ventilation in the workshop provides ventilation, cooling and ventilation, drying and dehumidification, cool in spring and autumn, and comfortable in summer and winter. The airflow generated by the rotation of the high pressure fan in the workshop and warehouse forms a cone from top to bottom and is pushed towards the ground. After reaching the ground, it flows in a horizontal direction. When encountering side barriers or horizontal airflow adjacent to the fan, it is pushed upward to the roof, thereby enhancing the air circulation in all directions and from multiple angles.

Related Keywords

Related Keywords