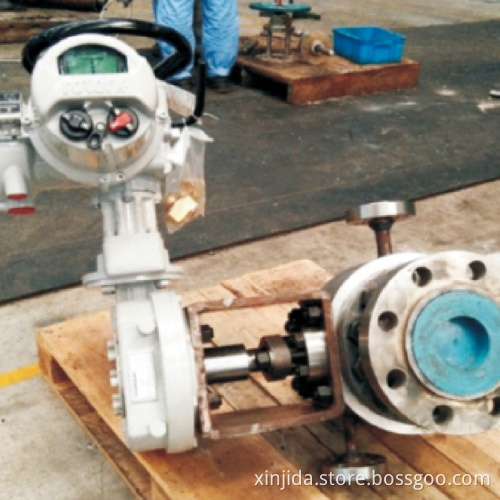

Special ball valves for industrial use

- Transportation:

- Ocean, Land

- Port:

- chongqing

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 5000 Piece/Pieces per Month |

| Supply Ability: | 5000 Piece/Pieces per Month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land |

| Port: | chongqing |

Product Description

Product Description

Special ball valve are a type of special valve widely used in industrial fluid systems, typically composed of balls, seats, stems, handles/operators, and seals. Compared to general ball valves, special ball valves have a more complex structure and stronger applicability, can adapt to higher pressure, temperature, medium type, and operating environment requirements, and can achieve higher flow rates and a wider range of pipeline connection options. Common types of special ball valve include the following:

Throttling ball valve: A throttling Control valve is a ball valve that achieves flow control through the throttling component inside the valve body. There is a regulating device above the valve stem, which adjusts the flow and pressure drop by operating the regulating valve stem and the structure above it. Due to its precise structure and high control performance, it is widely used in fluid control systems in fields such as chemical engineering, petroleum, natural gas, refrigeration units, etc.

Pneumatic ball valve: Pneumatic ball valve is a ball valve that controls the opening and closing of the valve body through a pneumatic actuator. Its implementation principle is to install a pneumatic actuator above the valve stem, which controls the air pressure inside the pneumatic actuator to move the valve stem up and down, thereby controlling the opening and closing of the valve. This valve is suitable for fluid control under harsh conditions such as high pressure, high temperature, and strong corrosion, and is widely used in automated fluid control systems in fields such as pharmaceuticals, chemicals, food and beverage, petroleum, and natural gas.

High temperature ball valve: High temperature ball valve refers to a ball valve that operates in a high temperature environment (usually above 400 ℃) and is specially designed, selected, and manufactured to withstand high temperature corrosion, high pressure, and high speed requirements. High temperature ball valves usually use metal materials (such as titanium, nickel, molybdenum, etc.) as the body and core materials to ensure their performance and reliability. High temperature ball valves are widely used in high-temperature pipeline fluid control systems in fields such as petroleum, chemical, power, metallurgy, and shipbuilding.

Throttling ball valve: A throttling Control valve is a ball valve that achieves flow control through the throttling component inside the valve body. There is a regulating device above the valve stem, which adjusts the flow and pressure drop by operating the regulating valve stem and the structure above it. Due to its precise structure and high control performance, it is widely used in fluid control systems in fields such as chemical engineering, petroleum, natural gas, refrigeration units, etc.

Pneumatic ball valve: Pneumatic ball valve is a ball valve that controls the opening and closing of the valve body through a pneumatic actuator. Its implementation principle is to install a pneumatic actuator above the valve stem, which controls the air pressure inside the pneumatic actuator to move the valve stem up and down, thereby controlling the opening and closing of the valve. This valve is suitable for fluid control under harsh conditions such as high pressure, high temperature, and strong corrosion, and is widely used in automated fluid control systems in fields such as pharmaceuticals, chemicals, food and beverage, petroleum, and natural gas.

High temperature ball valve: High temperature ball valve refers to a ball valve that operates in a high temperature environment (usually above 400 ℃) and is specially designed, selected, and manufactured to withstand high temperature corrosion, high pressure, and high speed requirements. High temperature ball valves usually use metal materials (such as titanium, nickel, molybdenum, etc.) as the body and core materials to ensure their performance and reliability. High temperature ball valves are widely used in high-temperature pipeline fluid control systems in fields such as petroleum, chemical, power, metallurgy, and shipbuilding.

The design and manufacturing of valves shall be in accordance with the provisions of API 608 and ASME B16.34

The structural length of the valve shall be in accordance with ASME B16.10

The end face connection size of the valve shall comply with the provisions of ASME B16.5

The inspection and testing of valves shall be in accordance with the provisions of API 598

Related Keywords

Related Keywords