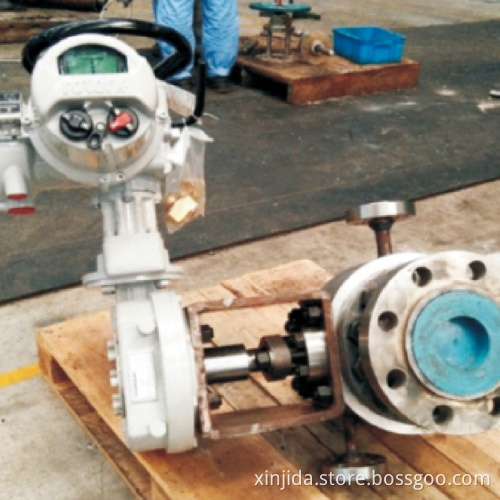

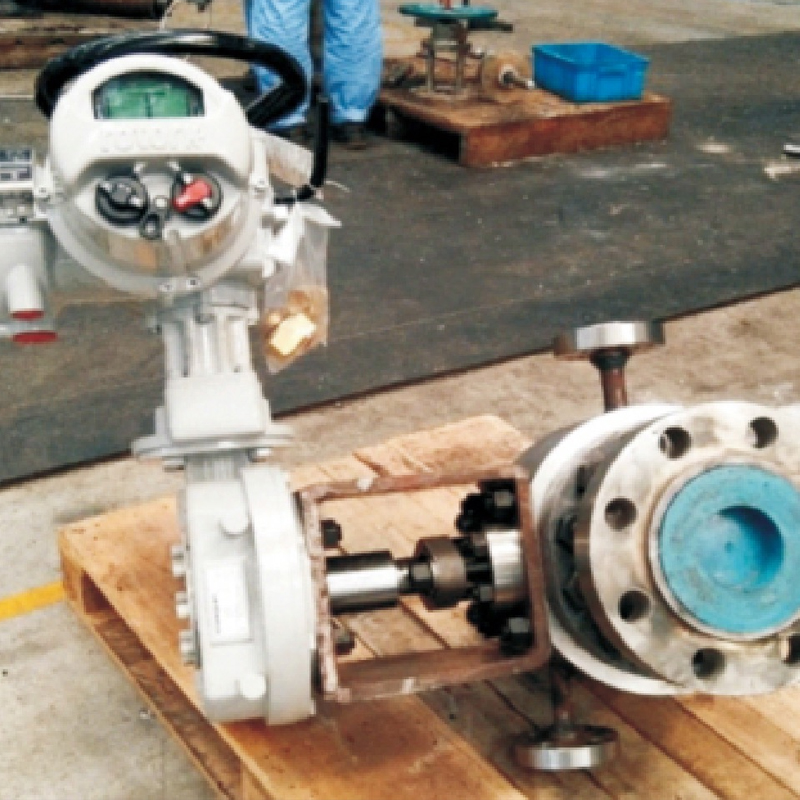

High temperature resistant special ball valve

- Transportation:

- Ocean, Land

- Port:

- chongqing

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 5000 Piece/Pieces per Month |

| Supply Ability: | 5000 Piece/Pieces per Month |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land |

| Port: | chongqing |

Product Description

Product Description

Special ball valve is a type of ball valve made of a special material or design, mainly used in some special industrial fields and occasions. Below is a brief introduction to the application scope of this special valve.

1. High temperature and high pressure applications

Special ball valves are mainly used in high-temperature and high-pressure industrial fields, such as oil refining, chemical, power, metallurgy, and other industries. In these industries, the pressure and temperature of liquids or gases are very high, so special high pressure valve are needed to meet these conditions to ensure safety and reliability of work. Tungsten molybdenum alloy and cobalt based alloy are currently the main materials used for manufacturing high-temperature and high-pressure special ball valves. These special materials can withstand extremely high temperatures and pressures, thereby ensuring the stability and reliability of ball valves.

2. Transportation pipelines for special media

Special media include corrosive media, high viscosity media, etc. These media generally cause serious corrosion or blockage problems to ordinary ball valves. To solve these problems, special ball valves are needed. At present, the special ball valve materials on the market mainly include ceramics, engineering plastics, special alloys, etc. These materials have excellent corrosion resistance and adhesion, which can effectively solve the problem of using special medium transportation pipelines.

Low temperature applications mainly refer to the use of low-temperature ball valves in the transportation process of liquid nitrogen, liquid oxygen, liquid methane, and other gases. These gases will condense and cause significant harm to the equipment when they come into contact with ball valves made of ordinary materials. To solve this problem, special materials such as stainless steel, copper alloy, etc. need to be used for ball valves, which can withstand extremely low temperatures to ensure safety and reliability in low-temperature applications.

4. Control of Special Fluids

Special fluids include high-purity water, biochemical agents, etc. The interactions and chemical reactions between these fluids are very complex, requiring special fluid control systems to control their flow and pressure. Special ball valves can be used as key components in control systems, enabling functions such as flow control and pressure control.

1. High temperature and high pressure applications

Special ball valves are mainly used in high-temperature and high-pressure industrial fields, such as oil refining, chemical, power, metallurgy, and other industries. In these industries, the pressure and temperature of liquids or gases are very high, so special high pressure valve are needed to meet these conditions to ensure safety and reliability of work. Tungsten molybdenum alloy and cobalt based alloy are currently the main materials used for manufacturing high-temperature and high-pressure special ball valves. These special materials can withstand extremely high temperatures and pressures, thereby ensuring the stability and reliability of ball valves.

2. Transportation pipelines for special media

Special media include corrosive media, high viscosity media, etc. These media generally cause serious corrosion or blockage problems to ordinary ball valves. To solve these problems, special ball valves are needed. At present, the special ball valve materials on the market mainly include ceramics, engineering plastics, special alloys, etc. These materials have excellent corrosion resistance and adhesion, which can effectively solve the problem of using special medium transportation pipelines.

Low temperature applications mainly refer to the use of low-temperature ball valves in the transportation process of liquid nitrogen, liquid oxygen, liquid methane, and other gases. These gases will condense and cause significant harm to the equipment when they come into contact with ball valves made of ordinary materials. To solve this problem, special materials such as stainless steel, copper alloy, etc. need to be used for ball valves, which can withstand extremely low temperatures to ensure safety and reliability in low-temperature applications.

4. Control of Special Fluids

Special fluids include high-purity water, biochemical agents, etc. The interactions and chemical reactions between these fluids are very complex, requiring special fluid control systems to control their flow and pressure. Special ball valves can be used as key components in control systems, enabling functions such as flow control and pressure control.

Related Keywords

Related Keywords