Anti-corrosion Tape, Anti corrosion Tape

-

$12.001-999 Square Meter

-

$0.861000-599999 Square Meter

-

$0.28≥600000 Square Meter

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shen Zhen Port, Qingdao, Dalian Port, Chongqing, Shanghai, Ningbo, Yiwu, Guangzhou Port, etc.

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 5000㎡/Daily |

| Supply Ability: | 5000㎡/Daily |

| Payment Type: | T/T,Paypal,Alibaba,West Union,Alipay,etc |

| Incoterm: | FOB,CIF,EXW,DDP,DDU,Express Delivery |

| Certificate: | CE,ISO,Quality Test Report,etc. |

| HS Code: | 7019909990 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shen Zhen Port,Qingdao,Dalian Port,Chongqing,Shanghai,Ningbo,Yiwu,Guangzhou Port,etc. |

Product Description

Product Description

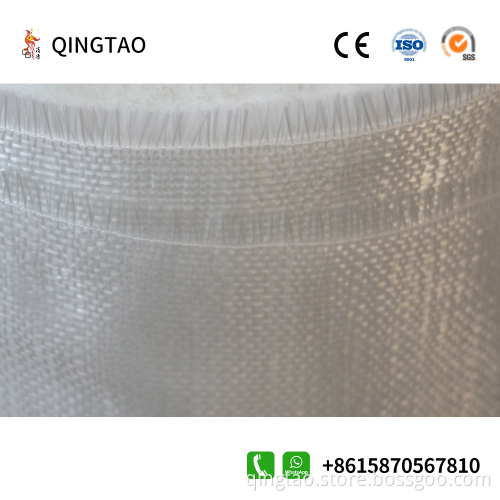

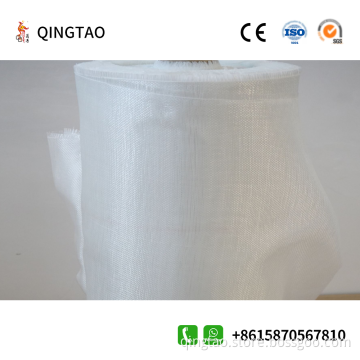

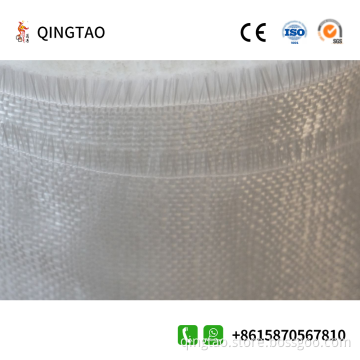

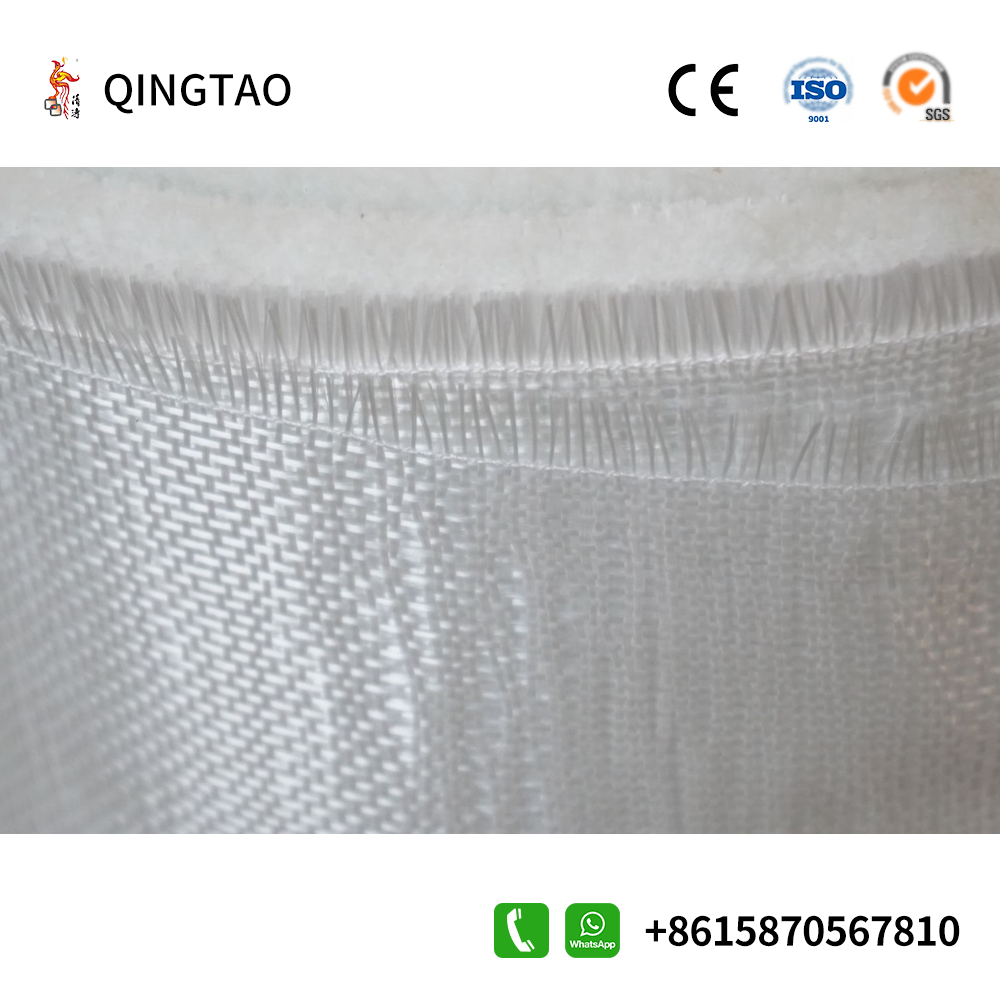

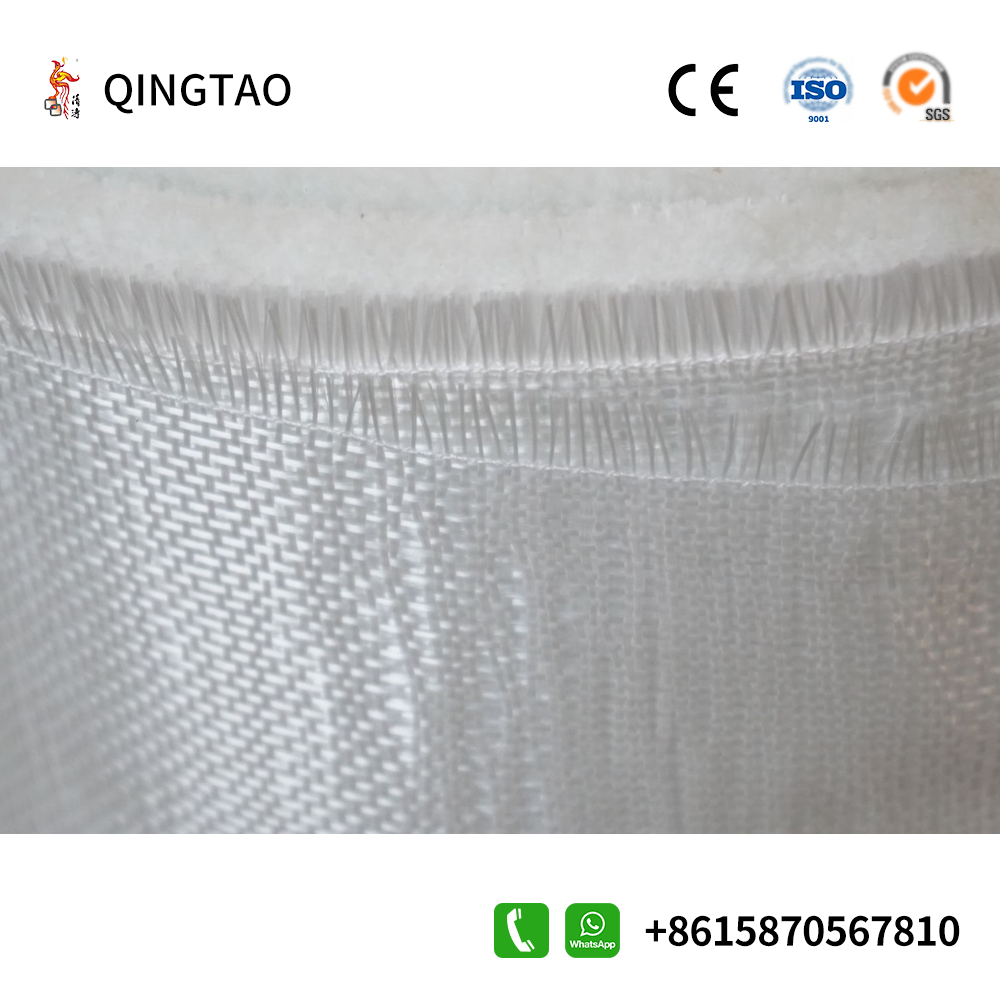

Anti Corrosive cloth 1.1 Construction (E glass) technology: Base surface treatment - first pass, first coat of epoxy resin primer - first pass, first pass of epoxy cement patching - first pass, first pass of inspection - first coat of epoxy cement top coat, second pass First, apply the second coat of epoxy resin primer - Apply the second coat of epoxy resin primer - Apply the glass fiber cloth until the required thickness - Apply the epoxy resin topcoat - Check if it is qualified - Complete and accept the work one and one.

1.2 Main construction methods:

1.2.1 Base surface treatment and damage repair

(1) For areas where the surface has fallen off and there are no sharp seams around it, directly use wire brushes, brushes, cleaning (Industrial Textiles) agents and other tools to clean away surface dirt, dust and small particles that are not firmly attached.

(2) If there are cracks and the cement structure is loose, use a grinder to cut along the cracks and remove the loose structure with a small hammer, chisel and other tools, and then clean the surface with a wire brush, brush, washing-up (Fireproof Cloth) liquid.

(3) For the peeling part less than 2.5cm2, use a dust nozzle hammer, chisel and other tools to expand the peeling part to 2.5cm2 and the depth to no less than 2cm, and then use a wire brush, brush, and cleaning agent to clean the (Anti Corrosion) surface.

(4) The treated base surface should be free of dust, organic matter, and loose particles. And the base surface has a certain roughness

(5) Use moderate force when cleaning the base surface, and do not use excessive force to avoid damaging solid parts.

(6) The base surface that has passed the treatment must be constructed in the next process within 8 hours. Otherwise, secondary processing is required.

1.2 Main construction methods:

1.2.1 Base surface treatment and damage repair

(1) For areas where the surface has fallen off and there are no sharp seams around it, directly use wire brushes, brushes, cleaning (Industrial Textiles) agents and other tools to clean away surface dirt, dust and small particles that are not firmly attached.

(2) If there are cracks and the cement structure is loose, use a grinder to cut along the cracks and remove the loose structure with a small hammer, chisel and other tools, and then clean the surface with a wire brush, brush, washing-up (Fireproof Cloth) liquid.

(3) For the peeling part less than 2.5cm2, use a dust nozzle hammer, chisel and other tools to expand the peeling part to 2.5cm2 and the depth to no less than 2cm, and then use a wire brush, brush, and cleaning agent to clean the (Anti Corrosion) surface.

(4) The treated base surface should be free of dust, organic matter, and loose particles. And the base surface has a certain roughness

(5) Use moderate force when cleaning the base surface, and do not use excessive force to avoid damaging solid parts.

(6) The base surface that has passed the treatment must be constructed in the next process within 8 hours. Otherwise, secondary processing is required.

Related Keywords

Related Keywords