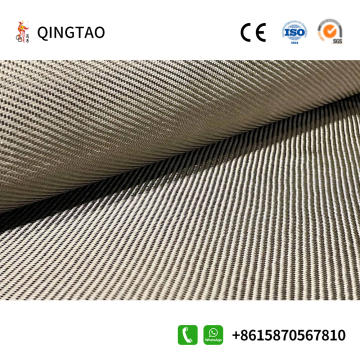

About Basalt Fiber Jet Yarn

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Chongqing Guoyuan Port, Yiwu, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Productivity: | 20 tons/daily |

|---|---|

| Supply Ability: | 20 tons/daily |

| Payment Type: | T/T,Paypal,Western Union,Alipay,Alibaba |

| Incoterm: | FOB,CIF,EXW,DDP,DDU |

| HS Code: | 6815994000 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Chongqing Guoyuan Port,Yiwu,Ningbo |

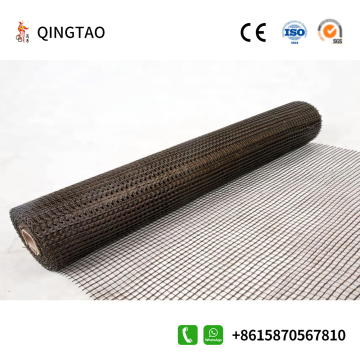

basalt stone is made by melting basalt ore at high temperature and drawing it. It has silicate similar to natural ore. It can be biodegraded in the environment after being discarded. It is Anti Corrosion and is an environmentally friendly Industrial Textiles.

The surface of basalt fiber is smooth and the surface energy is low. After surface modification, nano-SiO2 particles are added to the surface, which effectively improves the surface roughness of the fiber and increases the effective contact area between microorganisms and carriers; after modification, the surface has cationic If there is, the surface potential of the carrier increases, and the surface of the carrier is positively charged, using electrostatic attraction to promote the immobilization of microorganisms, which is beneficial to the immobilization of microorganisms; the active functional groups on the surface after modification increase the surface energy of the carrier, including hydroxyl, carbonyl or carboxyl groups, etc. , which has a positive effect on the adhesion and growth of microorganisms on the surface of the carrier. By modifying the surface of the basalt fiber carrier, it has good hydrophilicity and microbial loading performance, allowing it to load more biomass and maintain high microbial activity for a long time, thereby achieving more effective biofilm degradation. Pollutants in water bodies.

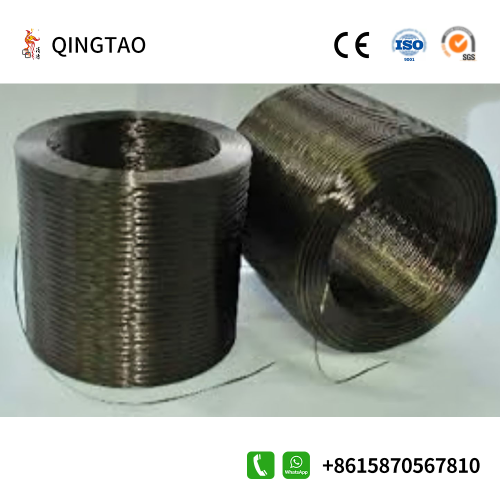

1. Production: It is made of continuous basalt fibers without twisting. The fiber surface is coated with alkali-resistant or modified epoxy sizing agent. It is mainly used for the reinforcement and toughening of (tunnel spraying) concrete and composite materials.

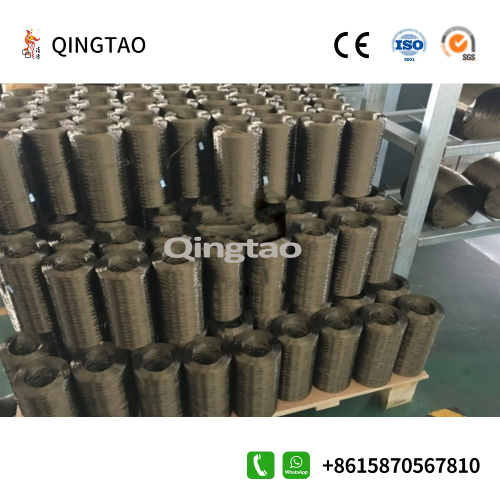

2. Packaging: 1000KG/pallet (18KG/piece).

3. Performance: high strength, good dispersion, less lint

4. Specification model: BFCS16-2400tex

BFCS: Basalt fiber spray yarn.

16: The fiber single filament diameter is 16 microns (um);

2400: The bus density is 2400tex (g/km), usually 2400-4800tex.

Technical indicators

Item

Industry Standard

GB/T25045

GB/T25045

GB/T25045

GB/T25045

GB/T25045

GB/T25045

Performance

≥0.4

2400±200

≤0.2

≥70

≥70

Internal control standards

≥0.45

2400±200

≤0.1

≥75

≥75

Related Keywords