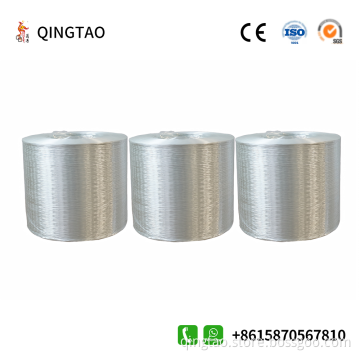

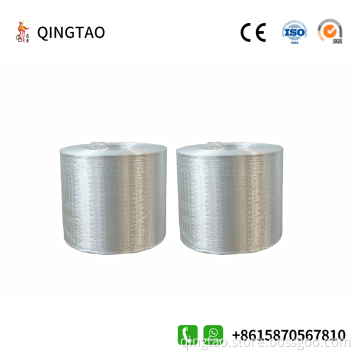

Fiberglass Chopped Strands For BMC

-

$1.801-999 Kilogram

-

$0.531000-5999 Kilogram

-

$0.46≥6000 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shen Zhen Port, Qingdao, Dalian Port

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 86 tons/daily |

| Supply Ability: | 86 tons/daily |

| Payment Type: | T/T,Paypal,Alibaba,West Union,Alipay,etc |

| Incoterm: | FOB,CIF,EXW,DDP,DDU |

| Certificate: | ISO,CE,Test Report,etc |

| HS Code: | 7019150090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shen Zhen Port,Qingdao,Dalian Port |

Product Description

Product Description

Chopped strands (grp material,e glass,e poxy) for BMC are compatible with unsaturated polyester, and epoxy resin and phenolic resin.The end uses include transportation, construction, electrical and ,with electronics, machinery and light industry.

BMC Proess

Bulk molding compounds is constituented of glass strands, resins, fillers, catalysts and other additives. The compound is processed through compression of molding or injection with molding to form the finished composite (resin epoxy resin,e glass,fiberglass )products (Fiberglass cloth) (Glass Mat) and (Fiber glass).

Mainly used to reinforce thermoplastics. Because of its good cost performance, it is especially fit for use as a reinforcing material for automobiles, trains, and shells when combined with resin: used in high-temperature with resistant needle punched felt, automobile sound-absorbing sheets, hot-rolled steel, etc. Its products are used in automobiles, construction, aviation, daily necessities and other fields. Typical products include auto parts, electronic and electrical products, mechanical (fabric fiberglass ) parts, etc.

It can also be used to enhance the anti-seepage and crack-resistant inorganic fibers of mortar concrete. It is also a very competitive product that can replace polyester fiber, lignin fiber and other products for reinforcing mortar concrete. It can also improve the high-temperature stability and low-temperature crack resistance of asphalt concrete and extend the service life of the road surface, etc.

BMC Proess

Bulk molding compounds is constituented of glass strands, resins, fillers, catalysts and other additives. The compound is processed through compression of molding or injection with molding to form the finished composite (resin epoxy resin,e glass,fiberglass )products (Fiberglass cloth) (Glass Mat) and (Fiber glass).

Product Specification

Item

Diameter(um)

Chopped Length(mm)

Compatible Resin

G

10-13

3

EP UP VE

H

10-13

4.5

EP UP VE

I

10-13

6

EP UP VE

J

10-13

12

EP UP VE

Mainly used to reinforce thermoplastics. Because of its good cost performance, it is especially fit for use as a reinforcing material for automobiles, trains, and shells when combined with resin: used in high-temperature with resistant needle punched felt, automobile sound-absorbing sheets, hot-rolled steel, etc. Its products are used in automobiles, construction, aviation, daily necessities and other fields. Typical products include auto parts, electronic and electrical products, mechanical (fabric fiberglass ) parts, etc.

It can also be used to enhance the anti-seepage and crack-resistant inorganic fibers of mortar concrete. It is also a very competitive product that can replace polyester fiber, lignin fiber and other products for reinforcing mortar concrete. It can also improve the high-temperature stability and low-temperature crack resistance of asphalt concrete and extend the service life of the road surface, etc.

Related Keywords

Related Keywords