fiberglass roving for gypsum/plaster

-

$1.781-999 Kilogram

-

$0.561000-599999 Kilogram

-

$0.34≥600000 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shen Zhen Port, Qingdao, Dalian Port

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 20 tons/daily |

| Supply Ability: | 20 tons/daily |

| Payment Type: | T/T,Paypal,Alibaba,West Union,Alipay,etc |

| Incoterm: | FOB,CIF,EXW,DDP,DDU,Express Delivery |

| Certificate: | ISO,CE,TEST REPORT,ETC. |

| HS Code: | 7019120090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shen Zhen Port,Qingdao,Dalian Port |

Product Description

Product Description

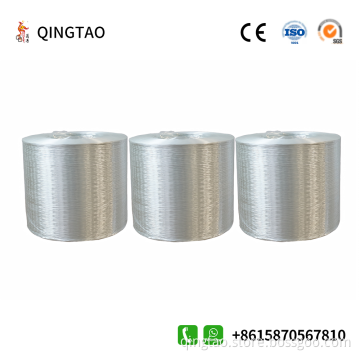

This Roving is specifically designed to reinforce for gypsum. It is choppedinto a specificlength and the chopis mixed with gypsum, starch powder and accelerating agent. Then the mixture is molded, cured, cut and dried to form a light weight construction boards.

| Product Specification | ||||||

| Item | TEX | LOl (%) | MOl (%) |

Filament

Tensile (N/TEX)

|

Compatible Resin |

Aplication

Process

|

| Fiberglass Gypsum Roving | 600-4800 | 0.95~1.30 | ≤0.10 | ≥0.3 | UP VE EP | Gypsum |

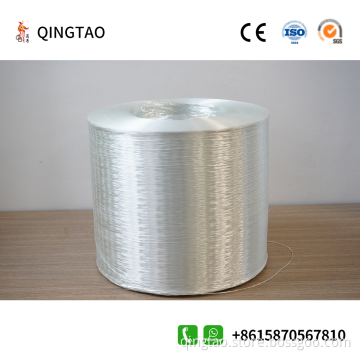

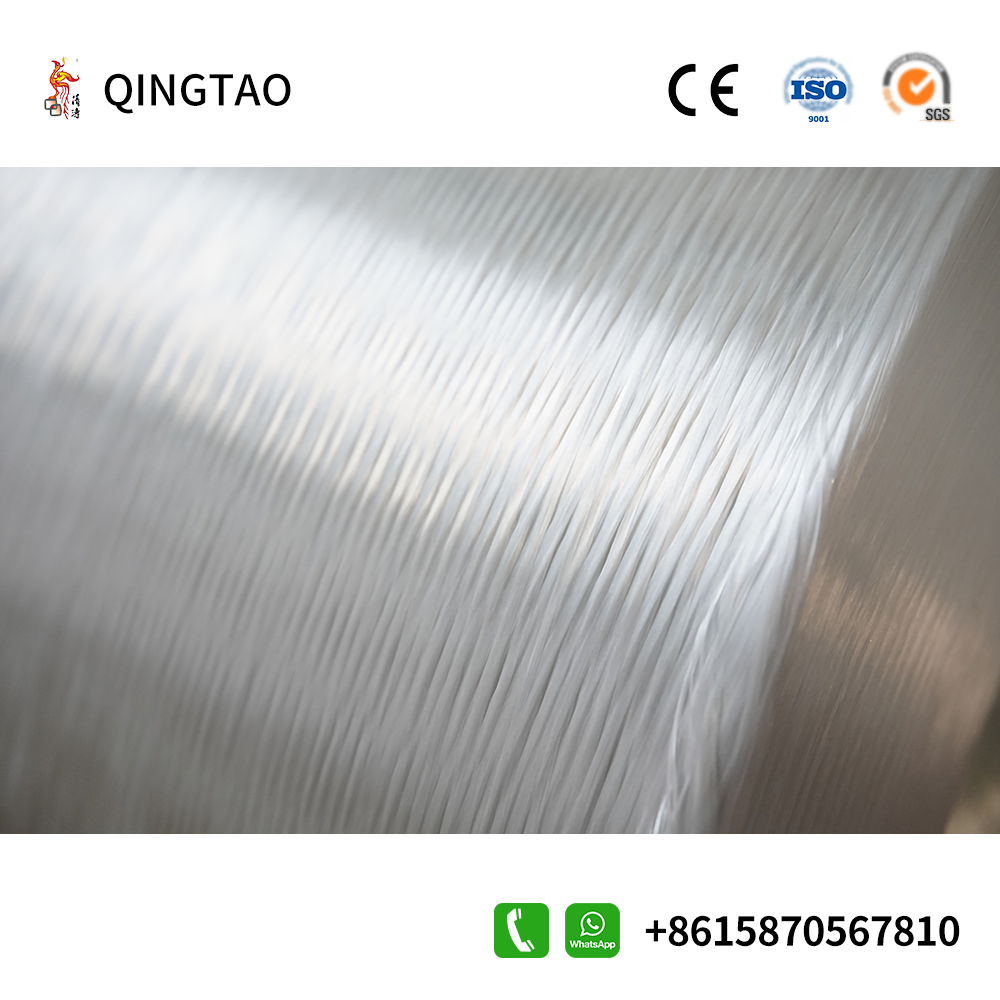

The main differences (glass yarn) between fiberglass roving and spun yarn include the following ( Glass fiber yarn) points:

Diameter ( Fiber glass ) difference:

The diameter of glass fiber spun yarn is less than 9μm.

In comparison, the diameter of roving is generally between 10 and 24 μm.

Strength and (Fiberglass cloth) Flexibility:

Because the diameter of the spun yarn is smaller and the fiber monomers are smaller, the spun yarn has higher strength (Fibreglass mat) and flexibility.

Rovings, although larger in diameter, have a higher fiber count and may therefore exhibit better mechanical properties in some applications.

use:

Due to its smaller diameter and higher strength, spun yarn is more suitable for manufacturing glass fiber products that require higher fiber strength, such as special fabrics.

Roving is widely used in infusion formulations or as a base material for blending with other ingredients.

Twisting condition:

Spun yarn is usually yarn with a single yarn diameter less than 10 microns and has no twist.

The single filament diameter of roving is more than 10 microns, and it can be straight yarn (untwisted parallel monofilament bundle) or stranded yarn (untwisted multi-strand roving bundle).

To sum up, there are obvious differences in diameter, strength, flexibility and use between fine yarns and roving yarns, and whether they are twisted will also affect the characteristics and application scenarios of the product.

Related Keywords

Related Keywords