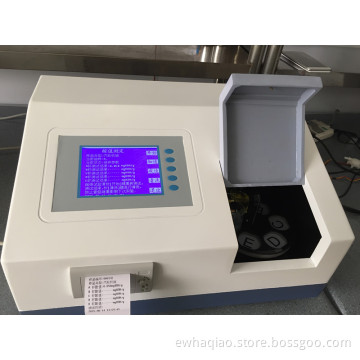

DGA 2010 Oil Gas Chromatography/ Insulating Oil Gas Chromatography/ Transformer Oil Gas Chomatography

on about the DGA2010:

We appreciate your choice for DGA2010 Gas Chromatography; your kind attention is invited to this instruction manual before running the equipment.

Equipped with large LCD displayer, DGA2010 is a micro-computer controlled GC with programmed 8-grade temperature rising function. Adopted with the advanced technology, DGA2010 has the function of power off protection, over-temperature protection, [0℃" protection, non-gas protection, auto ignition, and etc.

It has the characteristics of reliable performance, compact design, convenient operation, and good expandability. It has the special function of temperature tracking for column. Its standard configuration is FID & TCD while with the expanding detectors like ECD, FPD, and NPD as well as methane transforming furnace. It is also capable of configuring FID amplifier.

Now DGA2010 has been widely used in the industries like oil, chemistry, pesticides, wine, environment protection, epidemic prevention, universities, scientific research and etc.

1. Working Environment

Temperature: 0~30℃

Relative Humidity: <85%

No Strong Electromagnetic Field

No Corrosive Gas

Stable Working Table without Vibration

Power Supply: AC220V±10%,50Hz±0.5Hz

Power Consumption: 2KW Technical Parameters

1. Temperature Controlling

Chamber Temperature of Chromatographic Column

|

Temperature Range

|

RT + 8℃~420℃

|

|

Temperature Increment

|

1℃

|

|

Temperature Accuracy

|

±0.1℃ when < 200℃; ±0.2℃ when > 200℃

|

|

Temperature Uniformity

|

<1%

|

|

Temperature Error between Displaying & Real Temperature

|

<2%

|

|

Temperature Ramp Grades

|

8 Grades Linear

|

|

Temperature Ramp Rate

|

1~30℃/min with increment of 1℃/min

|

|

Time Range

|

0~255 min with increment of 1 minute

|

|

Temperature Repeatability

|

<2%

|

|

Max Heating Power

|

1500W

|

|

Temperature Sensor

|

PT100

|

Temperature of Vaporizing Room

|

Temperature Controlling Precision

|

±0.1℃ when <200℃; ±0.2℃ when >200℃

|

|

Temperature Range

|

<420℃

|

|

Heater

|

Standing Heating Facility with 100W Heater

|

|

Temperature Sensor

|

PT100

|

Chamber Temperature of FID

|

Temperature Controlling Precision

|

±0.1℃ when <200℃; ±0.2℃ when >200℃

|

|

Temperature Range

|

<420℃

|

|

Heater

|

Standing Heating Facility with 2×90W Heaters

|

|

Temperature Sensor

|

PT100

|

|

Sensitivity

|

S≥3000mv·ml/mg(Benzene, H2)

|

|

Noise

|

≤0.02mv

|

|

Drift

|

≤0.1mv/h

|

Built-in Amplifier

Semi-pervasion 100Ω bridge tungsten-rhenium wire

Constant Current Source Supply

|

|

Detection Limit

|

M≤2×10-11g/s (Benzene/SO2)

|

|

Noise

|

≤5×10-13A

|

|

Drift

|

≤5×10-12A/30min

|

|

Detection Limit on Programmed Temperature Control Mode

|

M≤1×10-9g/s

|

|

Drift on Programmed Temperature Control Mode

|

≤5×10-12A

|

|

All-collecting Polar Corundum Nozzle

Platinum Ignition Wire

|

4. Weight & Dimension

Dimension: 660(Width)× 460(Height)× 430(Depth)

Weight: 60kg

5. Optional Facilities

Recorder

-- Bench-top two-way recorder (Min Measurement: 1mv; Stroke Time: 1s)

-- Chromatogram Data Processor

-- Chromatogram Data Working Station (need to work with PC)

Gas Source

-- Nitrogen, Hydrogen, and Air tanks with Decompression Valves

-- Nitrogen, Hydrogen, and Air Generators

6-ways Gas Injector

Methane Reforming Furnace