Vacuum distillation process. Waste Lubricating Oil Recycling and Purification System--Vacuum Distillation.

Advantages of Vacuum Distillation Technology:

A2. Chemical cost--only 30$ for treat one ton waste oil

For one waste lube oil treatment, total Chemical cost is just 30USD , catalyst is the base chemicals in the market, normal and cheap, can find form market easily, there are hundred thousand supplier in China.

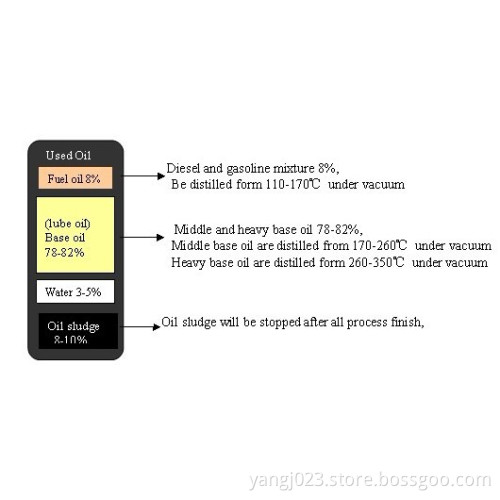

B2.regeneration rate---more than 85%,can separate gasoline, diesel and base oil under vacuum.

TY Vacuum distillation process .Waste lube oil will be heated more than 320℃ under vacuum ,the highest temperature is about 350℃ under vacuum. All part of cut, such as gasoline, diesel, light and heavy base oil in the used lube oil will be distilled out completely.

Vacuum distillation process can break the additive in the waste lube oil, then can decolor the waste black oil back to yellow(color standard is 1.5), also can separate fuel oil, base oil form the waste lube oil effectively and completely ,the regenerate rate is more than 85% as following:

C2.Environment friendly

TY Vacuum distillation process is sealed has high pressure sealed system. there is no any bad smell come out form the machine,after all cut of waste lube oil be distilled. There are just oil sludge stay the bottom of the distillation kettle, can be pump out us as bitumen and heavy fuel oil. no any high consumption chemical requires, easy to operate, good for operator and Environment.

Related Keywords